Dek . 28, 2024 16:03 Back to list

Removing Formwork from Concrete Slabs in Factory Settings for Efficient Construction

Removing Formwork for Concrete Slab A Comprehensive Guide

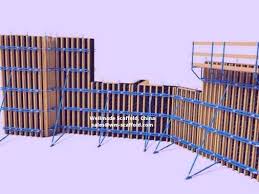

Formwork is an essential component in the construction of concrete slabs, providing the necessary temporary structure to shape and support the concrete until it cures and gains sufficient strength. Once the concrete reaches the required strength, the formwork can be removed. This process, although seemingly straightforward, requires careful consideration to ensure the integrity of the structure and the safety of workers. In this article, we will explore the key aspects involved in removing formwork for concrete slabs in a factory setting.

Understanding Formwork

Formwork serves multiple purposes in concrete construction. It not only holds the wet concrete in place, preventing it from flowing but also defines the shape and surface finish of the slab. In factory environments, where efficiency and precision are paramount, various types of formwork systems such as reusable panels or proprietary systems are often utilized. Choosing the right formwork is crucial for simplifying the removal process.

Timing for Removal

One of the most critical factors in removing formwork is timing. Concrete does not attain its full strength immediately after pouring; it must undergo a curing process. The timing for formwork removal is generally guided by the concrete's design strength, which is typically specified in structural engineering plans. In most cases, formwork can be removed when the concrete has reached at least 70% of its specified compressive strength, but this varies based on the type of concrete mix and environmental conditions.

To ascertain the right moment for formwork removal, construction teams often perform strength tests on concrete samples. Using a simple cone penetrometer test or more sophisticated methods, they can evaluate the hardness of the cured concrete before proceeding.

Safety Considerations

Safety is paramount during the removal of formwork. Improper handling can lead to accidents, including structural failures or injuries to workers. Key safety measures include

1. Personnel Training Ensuring that all workers involved in the formwork removal process are adequately trained is essential. They should understand the potential risks and correct procedures.

removing formwork for concrete slab factory

2. Inspection of Formwork and Concrete Before removal, it's crucial to inspect both the formwork and the concrete slab for any signs of under-curing or structural issues. This step helps identify potential weaknesses in the slab.

3. Use of Proper Equipment Utilize appropriate tools and equipment for dismantling formwork. Manual handling should be minimized where possible, with lifting aids employed to reduce the risk of injury.

4. Controlled Environment Maintain a clean and organized workspace to avoid accidents. Stray tools or debris can pose significant hazards during the removal process.

Techniques for Formwork Removal

Once the concrete has achieved sufficient strength and safety checks have been completed, the actual removal process can begin. Different techniques may be employed based on the type of formwork used

- Sequential Removal This method involves removing the formwork in a specific order to maintain the structural integrity of the slab. It's particularly useful in multi-layer systems.

- Gentle Tapping If the formwork is stuck due to the bonding with the concrete, gentle tapping with a rubber mallet can help free it without damaging the slab.

- Mechanical Assistance In larger factory settings, cranes or other lifting devices may be used to remove heavy formwork panels. This reduces manual labor and minimizes the risk of injury.

Conclusion

Removing formwork for concrete slabs is a critical process that requires careful planning, execution, and safety measures. By understanding the timing, safety considerations, and proper techniques involved, construction teams can ensure a smooth transition from formwork to a completed slab. In factory settings where efficiency and precision are vital, following these guidelines will lead to successful concrete construction projects, ultimately contributing to the overall quality and durability of the built environment.

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025