Каст . 03, 2024 21:51 Back to list

formwork wing nut with plate manufacturers

The Importance of Formwork Wing Nuts with Plates A Guide for Manufacturers

In the construction industry, the use of formwork is crucial for shaping and supporting structures during the pouring of concrete. Among the various components that make up formwork systems, wing nuts with plates stand out for their efficiency and reliability. These essential hardware items facilitate the secure connection between formwork panels, ensuring that they remain stable and properly aligned as concrete is poured.

What Are Formwork Wing Nuts with Plates?

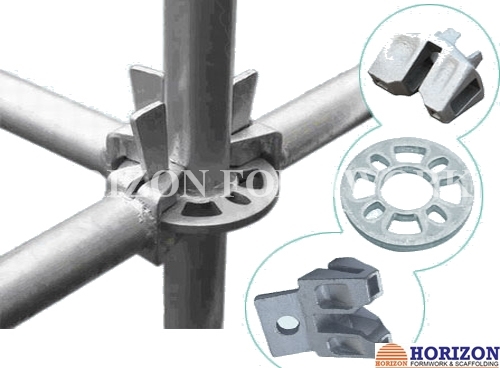

Formwork wing nuts are specialized fasteners designed to hold formwork ties in place. They typically feature a large, easily graspable wing design that allows for quick manual tightening, making the assembly process faster and more efficient. The attached plate provides additional surface area, distributing the clamping force to minimize damage to the formwork materials. This combination of functionality and ease of use makes wing nuts with plates a preferred choice among construction professionals.

Manufacturing Process

Manufacturers of formwork wing nuts with plates must adhere to strict quality standards to ensure product reliability. The production process generally involves several key steps

1. Material Selection The primary materials used in manufacturing wing nuts typically include steel and stainless steel for strength and durability. Corrosion-resistant coatings may also be applied to enhance longevity, especially in outdoor or moist environments.

2. Machining The manufacturing process often involves precision machining techniques to shape the nuts and plates accurately. This ensures that each component fits together seamlessly, which is vital for maintaining structural integrity during concrete pouring.

3. Quality Control Rigorous testing is essential to ensure that the wing nuts can withstand the high pressures exerted by wet concrete. Manufacturers often conduct tensile tests and check for dimensional accuracy to maintain quality.

formwork wing nut with plate manufacturers

4. Finishing Once the wing nuts are machined and inspected, they typically undergo finishing processes that may include galvanizing or powder coating. These treatments help protect against rust and wear, enhancing the product's lifespan.

Advantages of Using Wing Nuts with Plates

Manufacturers and construction teams reap several benefits from using formwork wing nuts with plates

- Ease of Use The wing design allows for simple hand tightening, reducing the need for additional tools and speeding up the assembly process.

- Secure Fastening The plates help distribute pressure evenly, which minimizes the risk of formwork blowouts and ensures a smoother concrete finish.

- Cost-Effectiveness Durable and reusable, these components can significantly lower costs over time by reducing the need for frequent replacements.

Conclusion

Formwork wing nuts with plates are a vital component in the effective management of concrete structures. For manufacturers, focusing on high-quality production processes and robust materials is crucial to meet the demanding needs of the construction industry. As the market continues to evolve, innovations in design and manufacturing techniques will likely enhance the efficacy and reliability of these essential construction tools.

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025