jun . 16, 2024 19:33 Back to list

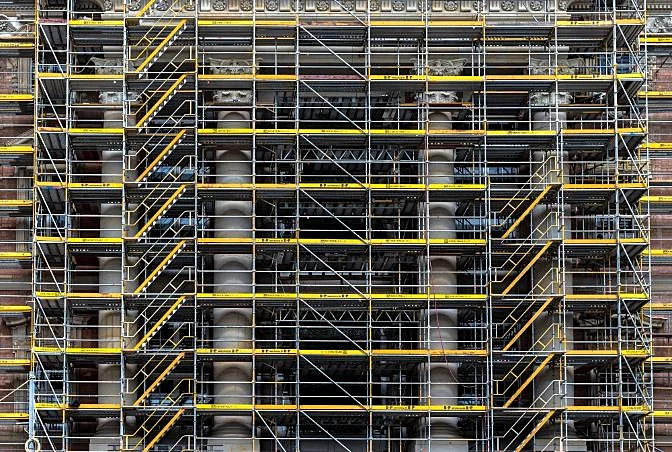

Concrete wall formwork pouring in factories.

Innovations in Concrete Pouring Wall Formwork Factories

In the realm of construction, the process of concrete pouring has always been a critical component, particularly when it comes to wall formwork. The efficiency and quality of these operations can make or break a construction project. As such, advancements in concrete pouring wall formwork factories have been at the forefront of innovation, aiming to improve productivity and reduce costs while ensuring structural integrity.

One of the most significant developments in this field has been the introduction of automated machinery. These high-tech systems are designed to streamline the entire wall formwork process, from the initial setup to the final dismantling. Automation not only speeds up the process but also enhances precision, minimizing errors that could compromise the stability of the walls being poured.

Another transformative shift has been the adoption of sustainable materials and practices. With an increasing global focus on eco-friendliness, many factories now prioritize the use of recyclable or reusable formwork materials. This approach not only aligns with environmental goals but also offers long-term economic benefits by reducing waste and reliance on single-use resources.

Digital integration is yet another trend that has taken root in modern concrete pouring wall formwork factories

Digital integration is yet another trend that has taken root in modern concrete pouring wall formwork factories Digital integration is yet another trend that has taken root in modern concrete pouring wall formwork factories

Digital integration is yet another trend that has taken root in modern concrete pouring wall formwork factories

Digital integration is yet another trend that has taken root in modern concrete pouring wall formwork factories

Digital integration is yet another trend that has taken root in modern concrete pouring wall formwork factories concrete pouring wall formwork factories. By integrating digital tools such as Building Information Modeling (BIM) and real-time data analytics, manufacturers can optimize design, forecast material needs more accurately, and monitor the curing process of the concrete. This technological edge ensures that every wall produced meets the highest standards of quality control.

Furthermore, there has been a surge in modular formwork designs. These prefabricated forms can be quickly assembled and disassembled on-site, significantly reducing labor requirements and shortening construction timelines. The modular approach also allows for greater flexibility in design, enabling the creation of unique and complex wall structures without sacrificing efficiency.

The evolution of concrete pouring wall formwork factories has been marked by a blend of automation, sustainability, digital integration, and modularity. These innovations are not just about staying ahead of the curve; they are about shaping a future where constructing buildings is not only faster and more economical but also kinder to our planet. As we look to the horizon of construction technology, one thing is clear the future of wall formwork is bright, innovative, and ever-improving.

concrete pouring wall formwork factories. By integrating digital tools such as Building Information Modeling (BIM) and real-time data analytics, manufacturers can optimize design, forecast material needs more accurately, and monitor the curing process of the concrete. This technological edge ensures that every wall produced meets the highest standards of quality control.

Furthermore, there has been a surge in modular formwork designs. These prefabricated forms can be quickly assembled and disassembled on-site, significantly reducing labor requirements and shortening construction timelines. The modular approach also allows for greater flexibility in design, enabling the creation of unique and complex wall structures without sacrificing efficiency.

The evolution of concrete pouring wall formwork factories has been marked by a blend of automation, sustainability, digital integration, and modularity. These innovations are not just about staying ahead of the curve; they are about shaping a future where constructing buildings is not only faster and more economical but also kinder to our planet. As we look to the horizon of construction technology, one thing is clear the future of wall formwork is bright, innovative, and ever-improving.

Digital integration is yet another trend that has taken root in modern concrete pouring wall formwork factories

Digital integration is yet another trend that has taken root in modern concrete pouring wall formwork factories

Digital integration is yet another trend that has taken root in modern concrete pouring wall formwork factories

Digital integration is yet another trend that has taken root in modern concrete pouring wall formwork factories concrete pouring wall formwork factories. By integrating digital tools such as Building Information Modeling (BIM) and real-time data analytics, manufacturers can optimize design, forecast material needs more accurately, and monitor the curing process of the concrete. This technological edge ensures that every wall produced meets the highest standards of quality control.

Furthermore, there has been a surge in modular formwork designs. These prefabricated forms can be quickly assembled and disassembled on-site, significantly reducing labor requirements and shortening construction timelines. The modular approach also allows for greater flexibility in design, enabling the creation of unique and complex wall structures without sacrificing efficiency.

The evolution of concrete pouring wall formwork factories has been marked by a blend of automation, sustainability, digital integration, and modularity. These innovations are not just about staying ahead of the curve; they are about shaping a future where constructing buildings is not only faster and more economical but also kinder to our planet. As we look to the horizon of construction technology, one thing is clear the future of wall formwork is bright, innovative, and ever-improving.

concrete pouring wall formwork factories. By integrating digital tools such as Building Information Modeling (BIM) and real-time data analytics, manufacturers can optimize design, forecast material needs more accurately, and monitor the curing process of the concrete. This technological edge ensures that every wall produced meets the highest standards of quality control.

Furthermore, there has been a surge in modular formwork designs. These prefabricated forms can be quickly assembled and disassembled on-site, significantly reducing labor requirements and shortening construction timelines. The modular approach also allows for greater flexibility in design, enabling the creation of unique and complex wall structures without sacrificing efficiency.

The evolution of concrete pouring wall formwork factories has been marked by a blend of automation, sustainability, digital integration, and modularity. These innovations are not just about staying ahead of the curve; they are about shaping a future where constructing buildings is not only faster and more economical but also kinder to our planet. As we look to the horizon of construction technology, one thing is clear the future of wall formwork is bright, innovative, and ever-improving. Latest news

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

H20 Timber Beam Enhanced with GPT-4-Turbo AI Design

NewsAug.01,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025

-

High Quality China Single Sided Wall Formwork for Retaining Walls

NewsJul.30,2025