aug . 20, 2024 22:38 Back to list

Innovative Solutions for Advanced Concrete Formwork in OEM Applications

Advanced Concrete Formwork Innovations in OEM Manufacturing

In the ever-evolving world of construction, the demand for efficient, durable, and cost-effective materials has led to significant advancements in concrete formwork systems. Original Equipment Manufacturers (OEMs) specializing in advanced concrete formwork are at the forefront of these innovations, providing solutions that enhance productivity, safety, and the overall quality of concrete structures.

Concrete formwork is a critical component in the construction industry, serving as temporary molds into which concrete is poured and set. The traditional wooden or metal formwork systems are being increasingly supplemented or replaced by advanced solutions that offer numerous advantages. OEMs in this field are leveraging cutting-edge design and manufacturing technologies to develop formwork systems that meet the diverse needs of modern construction projects.

Advanced Concrete Formwork Innovations in OEM Manufacturing

Another remarkable advancement is the introduction of modular and reusable formwork systems. These systems are designed to be easily assembled and disassembled, allowing for rapid reconfiguration to suit various project requirements. The modular approach enhances flexibility on-site, enabling construction teams to make swift changes without incurring significant downtime. Additionally, the reusability of these systems means that companies can reduce waste and lower their material costs over time, contributing to more sustainable construction practices.

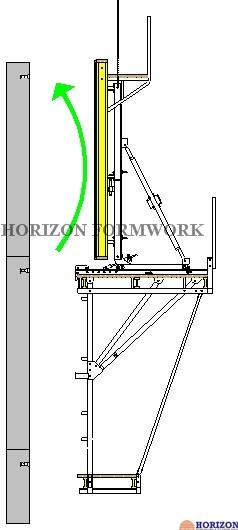

oem advanced concrete formwork

OEMs are also incorporating advanced technology into concrete formwork solutions. For instance, some manufacturers are utilizing digital modeling and simulation tools to optimize the design and performance of formwork systems. This allows for precise calculations and adjustments, ensuring that the formwork can withstand the pressures exerted by curing concrete. Moreover, the integration of sensors and IoT (Internet of Things) technology into formwork systems can provide real-time data on temperature, humidity, and pressure, allowing contractors to monitor the curing process remotely and make informed decisions.

Safety is another critical aspect that OEMs are addressing through advanced formwork designs. Innovative formwork systems minimize the risk of collapse and improve overall site safety. Features such as integrated safety rails and guard systems are becoming standard, ensuring that workers can operate with greater security. Furthermore, the ease of handling lightweight materials helps to alleviate the physical stress on laborers, promoting a safer working environment.

Finally, the customization capabilities offered by OEMs in developing advanced concrete formwork cannot be overlooked. With the growing complexity of architectural designs and structural requirements, the ability to tailor formwork solutions to specific project needs is invaluable. OEMs are able to collaborate closely with architects and engineers, providing bespoke formwork designs that not only enhance the aesthetic appeal of structures but also improve structural performance.

In conclusion, the advancements in concrete formwork driven by OEMs are revolutionizing the construction industry. Through the use of lightweight materials, modular systems, advanced technology, and an emphasis on safety and customization, these innovations are enhancing efficiency, reducing costs, and promoting sustainability. As the demand for more sophisticated construction solutions continues to grow, the role of advanced concrete formwork remains pivotal in shaping the future of building and infrastructure development.

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025