dec . 12, 2024 20:53 Back to list

timber beam h20 factory

Timber Beam H20 Factory Innovations in Construction Material

The construction industry has constantly evolved, finding new ways to create stronger and more sustainable structures. One notable advancement in this field is the use of engineered timber beams, particularly the H20 beam. As a cornerstone innovation, the H20 timber beam represents a remarkable breakthrough in enhancing the structural integrity and efficiency of construction projects. This article will delve into the characteristics, advantages, and the role of the H20 timber beam factory in producing this essential material.

The H20 timber beam is a type of engineered wood product, specifically designed to provide superior load-bearing capabilities while maintaining a lightweight structure. Its name derives from its unique cross-sectional shape resembling the letter H, which offers enhanced load distribution. The beam is made from layers of timber bonded together with adhesives, resulting in a product that is both strong and stable. The design minimizes deflection and reduces the likelihood of warping, which are common issues with traditional timber products.

Timber Beam H20 Factory Innovations in Construction Material

Additionally, the environmental benefits of using engineered timber cannot be overstated. H20 beams are often produced from sustainably sourced timber, promoting responsible forest management practices. By utilizing engineered wood products, the timber industry can reduce the amount of natural wood needed for construction, thus alleviating pressure on forests and contributing to a more sustainable future.

timber beam h20 factory

A thriving timber beam H20 factory plays an essential role in this innovative production process. Such factories utilize advanced technology and machinery to manufacture high-quality H20 beams that meet industry standards. These production facilities are equipped with automated cutting and gluing systems that enhance precision and consistency, ensuring that every beam produced meets the rigorous requirements of structural grading.

Quality control is a critical aspect of H20 beam manufacturing. Factories implement strict quality assurance protocols to monitor the structural integrity of each beam produced. This process ensures that the beams can withstand various loads and environmental conditions, providing peace of mind to builders and homeowners alike.

Moreover, timber beam H20 factories often prioritize research and development to continuously improve their products. Innovations in adhesive technologies and timber layer arrangements are regularly explored to enhance performance characteristics. Factories also collaborate with engineers and architects to tailor H20 beams for specific design needs, further emphasizing their versatility in construction.

In conclusion, the H20 timber beam stands out as a prominent solution within the construction industry, offering a perfect blend of strength, lightweight properties, and sustainability. The evolution of timber beam H20 factories has led to improved manufacturing processes that provide builders with reliable and efficient materials. As the demand for environmentally friendly building solutions continues to grow, it is clear that H20 beams will remain a pivotal element in shaping the future of construction. By investing in state-of-the-art factories and fostering innovation, the timber industry ensures that it is well-prepared to meet the challenges of modern architecture while contributing positively to the environment.

-

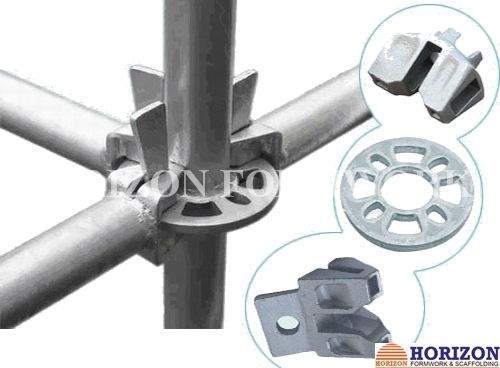

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025