Set . 16, 2024 20:29 Back to list

formwork water stop wing nut suppliers

Understanding the Importance of Formwork Water Stop Wing Nuts in Construction

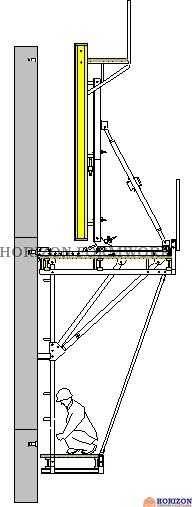

In the intricate world of construction, the importance of effective formwork cannot be overstated. Formwork essentially serves as a temporary structure used to mold concrete into the desired shape until it hardens. Among the various components that ensure the efficiency and reliability of formwork, water stop wing nuts have emerged as critical fittings, particularly for projects involving concrete in wet conditions or areas prone to water ingress.

What are Water Stop Wing Nuts?

Water stop wing nuts are specialized fasteners designed to secure formwork and prevent the leakage of liquid concrete during the pouring process. They are typically used in conjunction with a water stop, a crucial component that acts as a barrier to water infiltration. The design of the wing nut allows for easy handling and manipulation, enabling construction workers to tighten or loosen fastenings quickly and efficiently. This feature is particularly valuable in time-sensitive projects where speed can significantly affect overall productivity.

Why are They Essential?

1. Preventing Leakage The primary function of water stop wing nuts is to create a watertight seal during concrete pouring. If the concrete seeps through gaps, it can compromise the integrity of the structure and lead to structural failures. By securely fastening the formwork together, these wing nuts help achieve a leak-resistant environment.

2. Safety Properly secured formwork reduces the risk of accidents on-site. Unsecured formwork can shift or collapse under the weight of wet concrete, posing risks to workers and potentially causing costly delays. Wing nuts, with their robust design, contribute to a safer working environment.

formwork water stop wing nut suppliers

3. Efficiency The installation and adjustment of water stop wing nuts are designed to be quick, allowing workers to set up formwork more efficiently. This efficiency translates to reduced labor costs and quicker project turnaround times, enhancing overall productivity.

4. Durability Water stop wing nuts are typically constructed from high-quality materials that can withstand the harsh conditions of construction sites. Resistance to corrosion and wear ensures that they maintain their integrity over multiple uses, making them a cost-effective solution for constructors.

Choosing the Right Supplier

When it comes to sourcing water stop wing nuts, choosing a reliable supplier is paramount. A good supplier will offer high-quality products that adhere to industry standards, ensuring you receive items that perform effectively under demanding conditions. Additionally, look for suppliers with a solid reputation, excellent customer service, and a wide range of products. Many suppliers also provide technical support and advice, which can be invaluable in making the right choices for your specific project requirements.

Conclusion

In summary, water stop wing nuts are an indispensable element of modern construction. Their ability to secure formwork and prevent water ingress contributes significantly to the safety, efficiency, and durability of construction projects. By selecting the right suppliers for these essential components, contractors can ensure their projects are executed smoothly and successfully. Investing in high-quality materials like water stop wing nuts ultimately leads to more robust infrastructure and a safer construction environment.

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

H20 Timber Beam Enhanced with GPT-4-Turbo AI Design

NewsAug.01,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025

-

High Quality China Single Sided Wall Formwork for Retaining Walls

NewsJul.30,2025