Dis . 13, 2024 11:42 Back to list

oem shuttering for beam

Understanding OEM Shuttering for Beams A Comprehensive Overview

In the construction industry, the term shuttering refers to the temporary formwork used to hold freshly poured concrete in place until it sets and gains sufficient strength. This process is crucial for various structural elements, especially beams, which play a vital role in supporting loads in buildings and other structures. This article delves into OEM (Original Equipment Manufacturer) shuttering for beams, exploring its significance, benefits, and applications.

What is OEM Shuttering?

OEM shuttering refers to the formwork solutions that are designed and manufactured by specialized companies that produce equipment for various construction needs. These companies often tailor their products to meet the unique requirements of different construction projects. The term OEM emphasizes that the shutters are produced by a recognized manufacturer, ensuring quality and reliability in their design and functionality.

Significance of Beam Shuttering

Beams are fundamental components in construction; they distribute loads horizontally across structures. The proper formation of concrete beams requires high-quality shuttering to achieve the desired shape, size, and finish. The use of OEM shuttering systems helps to maintain consistent dimensions and integrity during the curing process of concrete.

High-quality beam shuttering ensures that the concrete sets properly, minimizing the risk of defects such as cracking, leakage, or weak points. These shutters can be customized based on project specifications, allowing for a variety of shapes, sizes, and materials depending on structural requirements.

Benefits of Using OEM Shuttering for Beams

1. Quality Assurance OEM shuttering products generally come with quality assurances that help prevent construction defects. Manufacturers adhere to strict standards and regulations, ensuring that the materials used are up to par.

oem shuttering for beam

2. Customization One of the most significant advantages of OEM shuttering is the ability to customize the formwork to meet specific project needs. Different projects might require unique shapes and designs, and OEM manufacturers can provide tailored solutions.

3. Time Efficiency Using pre-fabricated OEM shuttering can significantly reduce the time required for setting up formwork. Since these products are designed for quick assembly and disassembly, they help streamline the overall construction process.

4. Cost-Effectiveness Although the initial investment might be higher, OEM shuttering can save money in the long run. High-quality formwork minimizes waste and reduces the potential costs associated with repairs or defects in the concrete.

5. Reusability Many OEM shuttering systems are designed for multiple uses, making them a sustainable option. This reusability not only aids in reducing material costs but also supports eco-friendly building practices.

Applications of OEM Shuttering

OEM shuttering for beams is applied across various construction projects, including residential buildings, commercial structures, bridges, and more. Each application may require different types of beams—such as T-beams, L-beams, or cantilever beams—necessitating specialized shuttering systems for optimal results.

In high-rise constructions, for example, the load-bearing beams need to be robust and precisely formed. OEM shuttering solutions provide the necessary technical specifications to achieve this goal, ensuring safety and structural integrity.

Conclusion

OEM shuttering for beams is a critical component in modern construction that enhances the efficiency, quality, and safety of structural projects. By using tailored, high-quality shuttering solutions, builders can ensure that concrete beams are formed correctly, leading to durable and reliable structures. With advancements in manufacturing technologies and materials, OEM shuttering continues to evolve, offering new possibilities for the future of construction. As the industry grows, the importance of quality formwork becomes increasingly evident, solidifying the role of OEM solutions as fundamental to successful construction practices.

-

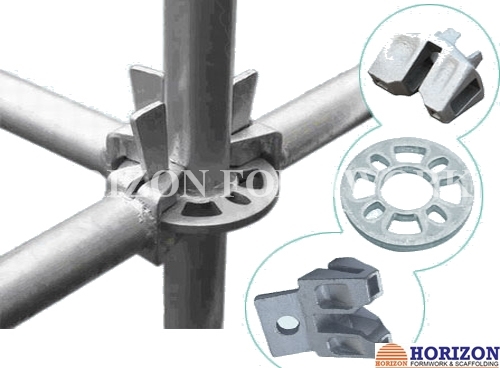

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025