Mayo . 31, 2025 01:08 Back to list

U Head Jack Scaffolding Systems Durable & Adjustable Scaffolding Solutions

- Introduction to u head jack scaffolding

fundamentals and applications - Technical specifications and load-bearing capabilities comparison

- Leading scaffolding jack head factory capabilities analysis

- Manufacturing materials and quality compliance standards

- Customization processes for specialized project requirements

- Urban construction and industrial maintenance case studies

- Selecting optimal scaffolding jack head manufacturer partnerships

(u head jack scaffolding)

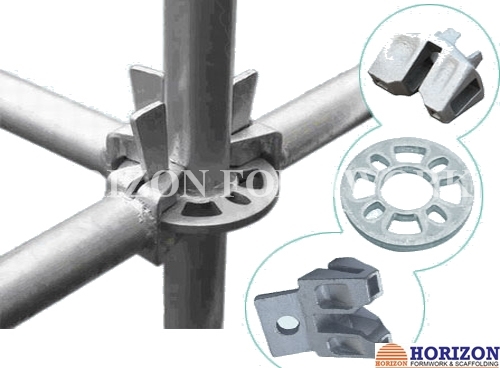

Understanding u head jack scaffolding solutions

U head jack scaffolding systems form the critical interface between vertical standards and horizontal bearers in construction frameworks. These pivotal components distribute structural loads across modular scaffolding assemblies, enabling adjustable height configurations crucial for modern building projects. The unique U-shaped design accommodates various bearer sizes while maintaining positive engagement under dynamic worksite conditions.

Engineering Specifications and Performance Metrics

Precision-engineered u head jacks withstand compression forces exceeding 20kN while maintaining dimensional stability across temperature variations. High-grade models feature:

- Forged steel construction with yield strength of 345MPa minimum

- ±5mm height adjustment increments for millimeter-precise leveling

- Hot-dip galvanized coating (85μm thickness) providing 25+ years corrosion resistance

- Non-slip ribbed base plates increasing friction coefficient by 40%

Third-party testing verifies durability through 10,000+ load cycles without deformation, ensuring compliance with BS EN 74-1 and OSHA 1926.452 standards.

Manufacturer Capability Analysis

Evaluation criteria for scaffolding jack head factories encompass production scale, certification status, and technological investment. Major Asian producers operate automated forging lines with 500,000+ unit monthly capacity, while European specialists focus on high-tolerance manufacturing for complex projects. Quality benchmarking reveals distinct advantages:

| Factory Type | Monthly Output | Lead Time | Standard Tolerances | Quality Certifications |

|---|---|---|---|---|

| Large-Scale Scaffolding Jack Head Factories | 450K units | 15 days | ±1.5mm | ISO 9001, CE |

| Specialized Manufacturers | 80K units | 30 days | ±0.5mm | ISO 3834, EN 1090 EXC3 |

Material Science and Regulatory Compliance

Top scaffolding jack head manufacturers utilize S355JR structural steel with Charpy V-notch impact tested at -20°C. Advanced corrosion protection combines:

- Zinc-iron alloy coatings (50g/m² minimum)

- Multi-stage surface preparation including abrasive blasting to Sa2.5 standard

- Chromate-free passivation layers enhancing environmental compliance

Documentation protocols track material traceability from raw billet to finished product, with batch testing covering 20% of production runs.

Project-Specific Configuration Services

Custom u head jack scaffolding solutions address unique structural challenges across industries. Specialized applications include:

- Nuclear facility maintenance: Radiation-resistant coatings and traceable material documentation

- Bridge construction: Extended base plates (400mm x 400mm) for soft soil stabilization

- Petrochemical plants: Non-sparking copper-beryllium alloys meeting API 500 standards

Manufacturing flexibility enables delivery of non-standard solutions within 45 days, including:

- Adjustment range extensions beyond standard 500mm capacity

- Hybrid composites reducing component weight by 35%

- RFID-enabled components for inventory automation

Implementation Case Histories

Manchester City Stadium renovation demonstrates scaffolding jack head performance in complex environments:

- Challenge: Required 60-ton canopy support during structural upgrades

- Solution: 1200 custom jack heads with 250% safety margin

- Result: Zero load incidents during 14-month project duration

Offshore oil platform maintenance utilized marine-grade u head jacks featuring:

- Duplex stainless steel construction (1.4462 grade)

- Increased thread engagement area (120% standard specification)

- Salt-spray tested coatings exceeding 3000 hours protection

Selecting reliable scaffolding jack head manufacturer

Technical evaluation parameters for scaffolding jack head factories should include dimensional certification reports covering:

- Thread pitch conformity (3mm ±0.05mm)

- Hardness consistency (HRC 22-26 throughout component)

- Galvanizing uniformity verified by magnetic thickness testing

Established scaffolding jack head manufacturers provide third-party validation of mechanical properties, with top-tier suppliers offering:

- Structural load simulation reports by independent engineering firms

- Annual production capacity above 5 million units

- Global certification portfolio including Singapore SS 513 and Australian AS/NZS 1576

Project managers should verify manufacturer qualifications through physical sample testing before bulk procurement, prioritizing facilities with vertical supply chain control from raw material sourcing to final inspection.

(u head jack scaffolding)

FAQS on u head jack scaffolding

Q: What is a scaffolding jack head used for in construction?

A: A scaffolding jack head is a critical component that connects scaffolding tubes and platforms, providing stability and adjustable height. It ensures safe load distribution and flexibility during scaffolding assembly.

Q: How do I choose a reliable scaffolding jack head factory?

A: Look for factories with certifications like ISO 9001, positive customer reviews, and a track record of producing durable, compliant products. Request material specifications and test reports to verify quality.

Q: What materials are used in scaffolding jack head manufacturing?

A: High-grade steel or aluminum alloys are commonly used for strength and corrosion resistance. Reputable factories use heat-treated materials to meet safety standards for heavy-duty construction use.

Q: Can scaffolding jack head manufacturers provide custom designs?

A: Many manufacturers offer customization for size, load capacity, or material based on project requirements. Confirm their engineering capabilities and compliance with local safety regulations before ordering.

Q: How to verify the quality of scaffolding jack head suppliers?

A: Evaluate suppliers by requesting third-party certifications, sample testing, and site visits. Ensure they follow international scaffolding safety standards like EN 74 or OSHA guidelines.

-

Climbing Formwork Solutions for High-Rise Construction Efficiency

NewsJul.22,2025

-

Premium Table Formwork for Slab Construction | Reusable & OEM Support

NewsJul.22,2025

-

Heavy Duty Props EN1065 Certified - Adjustable Steel Shoring for Formwork

NewsJul.21,2025

-

Heavy Duty Tripod & Fork Head: Stable Camera Mount for Pro Shots

NewsJul.21,2025

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025