Aug . 05, 2024 17:11 Back to list

Wall Formwork Solutions for Manufacturers Focusing on Quality and Efficiency in Construction Projects

Formwork for Walls A Guide for Manufacturers

In the construction industry, forming systems play a crucial role in shaping the structures that define our built environment. Among these systems, formwork for walls stands out due to its centrality in ensuring both the integrity and aesthetics of buildings. Manufacturers of formwork for walls must navigate a complex landscape filled with innovation, sustainability demands, and evolving construction practices.

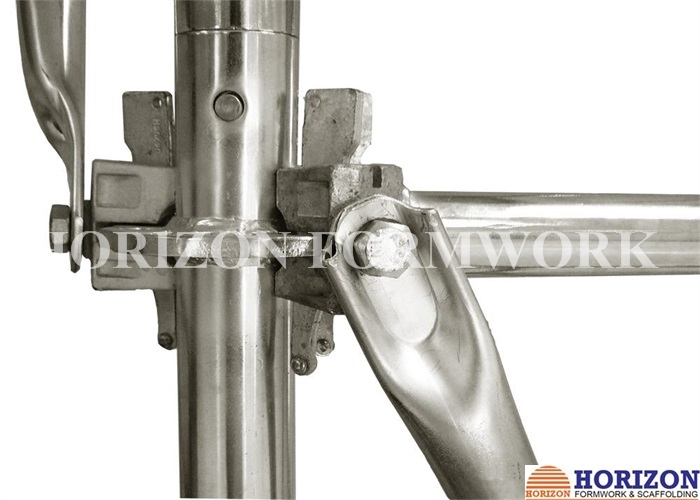

Formwork serves as a mold to shape concrete until it sets, providing support and maintaining the desired contour of the architecture. Various types of formwork exist, including traditional timber formwork, steel formwork, aluminum formwork, and today’s increasingly popular modular wall systems. Each has distinct advantages and potential drawbacks, influencing a manufacturer's choice based on project requirements.

Formwork for Walls A Guide for Manufacturers

Innovations in formwork technology, particularly in modular and pre-fabricated systems, have revolutionized wall construction. Modular formwork components are designed for easy assembly, reducing labor time on-site and increasing productivity. These systems enable a higher degree of precision, resulting in better quality concrete finishes and less wasted material. Manufacturers who invest in designing and producing modular systems can significantly enhance their competitive edge in the market.

formwork for walls manufacturers

Sustainability is at the forefront of construction practices today, and formwork manufacturers are responding. The industry is increasingly turning to eco-friendly materials and processes. For example, the use of recycled materials in formwork construction not only reduces waste but also appeals to environmentally conscious clients. Additionally, the push for sustainable practices encourages manufacturers to develop innovative designs that minimize material usage while maximizing efficiency and strength.

Furthermore, as smart technology permeates various industries, formwork systems are not left behind. The integration of smart sensors within formwork can provide real-time data on temperature, humidity, and concrete curing processes. Such technology enables manufacturers and contractors to make informed decisions, potentially reducing operational costs and improving project outcomes. This digital trend in the construction sector is creating new opportunities for manufacturers to differentiate their products and services.

When it comes to safety, manufacturers of wall formwork must also prioritize the development of safe systems. The construction site poses numerous hazards, and ensuring that formwork is stable and secure is critical to the safety of workers. Manufacturers can enhance safety by designing formwork that incorporates safety features, such as straightforward assembly instructions and inherent stability properties.

In conclusion, manufacturing formwork for walls encompasses a wide array of considerations, from material selection to innovative design and sustainability practices. As the construction industry continues to evolve, manufacturers have the opportunity to lead by embracing new technologies, adopting sustainable methods, and ensuring the highest safety standards. Doing so not only fulfills market demands but also contributes to the creation of resilient and sustainable structures that will stand the test of time. By staying ahead of these trends, manufacturers can position themselves as the go-to experts in wall formwork, driving both their success and the advancement of the construction industry as a whole.

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

H20 Timber Beam Enhanced with GPT-4-Turbo AI Design

NewsAug.01,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025

-

High Quality China Single Sided Wall Formwork for Retaining Walls

NewsJul.30,2025