Dec . 30, 2024 10:37 Back to list

wood formwork concrete exporter

Wood Formwork in Concrete Construction A Key Component for Exporters

The construction industry continues to evolve, embracing innovative materials and advanced technologies. However, one age-old method remains integral to the process wood formwork. This traditional technique is especially significant for countries that export concrete products, as wood formwork provides a versatile, reliable, and cost-effective solution for shaping poured concrete.

Understanding Wood Formwork

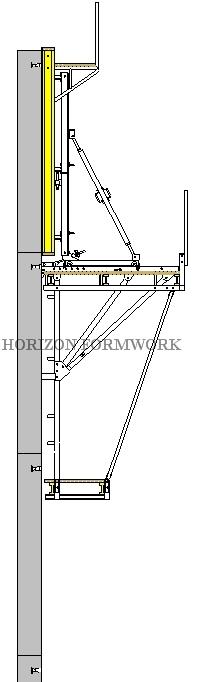

Wood formwork refers to temporary structures made from wooden panels, designed to hold wet concrete in place as it hardens. This method is widely used for various construction projects, from residential buildings to massive infrastructure developments. The success of wood formwork lies in its adaptability; it can be customized to fit any shape or size required by the construction project, making it an invaluable tool for concrete exporters.

One of the primary advantages of wood formwork is its ease of use. Wood is readily available in many regions, making it an accessible option for contractors and builders. Additionally, wood is relatively lightweight compared to other materials, allowing for easier handling and transportation. These characteristics make wood formwork a preferred choice among exporters striving to minimize costs and optimize efficiency in their operations.

Environmental Considerations

In recent years, sustainability has become a focal point in the construction industry. Importantly, wood is a renewable resource, especially when sourced from sustainably managed forests. Many concrete exporters are increasingly aware of the environmental impact of their operations, and opting for wood formwork aligns well with their sustainability goals. Utilizing eco-friendly materials not only improves a company's public image but can also open up new markets where consumers prioritize environmentally responsible practices.

Moreover, advancements in wood preservation and finishing technology have made it possible to enhance the durability and lifespan of wood formwork. This innovation means that wood formwork can be reused multiple times before it needs replacement, further reducing waste and promoting sustainability in concrete construction.

wood formwork concrete exporter

Challenges and Solutions

While wood formwork offers numerous benefits, concrete exporters also face challenges. One of the most significant issues is the potential for warping and degradation over time, particularly in challenging weather conditions. To counteract this, modern treatments and finishes apply protective coatings to wood formwork, providing not only structural integrity but also extending the material's usable life.

Additionally, the logistics of sourcing, transporting, and storing wood can be complex, particularly in international markets. Exporters must ensure that they comply with international standards for timber, which often require certifications to prove that the wood is harvested sustainably. Investing in a robust supply chain and developing relationships with reliable suppliers can help overcome these challenges and streamline the export process.

The Global Market for Wood Formwork

In the global construction market, the demand for high-quality wood formwork is on the rise. Emerging economies, particularly in Asia and Africa, are experiencing rapid urbanization and infrastructure development, presenting substantial opportunities for concrete exporters. As these countries invest in large-scale construction projects, the demand for efficient and effective formwork solutions continues to grow.

Furthermore, the versatility of wood formwork allows exporters to compete in diverse regions and sectors. Whether used in residential projects, commercial buildings, or civil engineering tasks, wood formwork can cater to various construction needs. This adaptability ensures that companies can maintain a steady demand for their products.

Conclusion

In conclusion, wood formwork remains a critical element of concrete construction, particularly for exporters. Its benefits, including cost-effectiveness, versatility, and sustainability, make it a favored choice in various markets. As the demand for concrete construction continues to grow globally, it is essential for exporters to embrace wood formwork as a key component of their strategy. By addressing challenges through innovation and sustainability practices, companies can enhance their competitiveness in the evolving construction landscape. With the right approach, the future of wood formwork in the export market looks bright, promising continued growth and expansion for those who recognize its potential.

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025