Lis . 06, 2024 01:48 Back to list

Overview of H2O Beam Specifications and Features for Optimal Performance

Understanding H20 Beam Specifications A Comprehensive Guide

The H20 beam is a widely used component in construction and engineering, notable for its structural integrity, efficiency, and versatility. Understanding its specifications is crucial for engineers, architects, and builders who aim to utilize this beam in various applications. In this article, we will delve into the essential characteristics, applications, and advantages of the H20 beam.

What is an H20 Beam?

The H20 beam, commonly known as the I-beam or H-beam, is a steel beam with a cross-sectional profile resembling the letter H. The “H” shape provides significant strength and stability, making it an ideal choice for frameworks in buildings, bridges, and other construction projects. The H20 specifically indicates a certain depth and width of the beam, typically denoting a nominal measurement in centimeters.

Key Specifications

1. Dimensions The H20 beam generally has a depth of approximately 20 centimeters (or 200 mm) and a width that varies based on specific engineering requirements. Some common widths for H-beams include 100 mm, 150 mm, or 200 mm, depending on the load-bearing capacity required for the application.

2. Weight The weight of the H20 beam is a critical factor that affects handling and transportation. These beams are available in various weight categories, allowing builders to select options that best suit their load requirements and design specifications.

3. Material Composition Typically manufactured from structural steel, the H20 beam boasts exceptional tensile strength and durability. The steel is often treated for corrosion resistance, ensuring its longevity in outdoor environments.

4. Load Capacity One of the most essential aspects of H20 beams is their load-bearing capability. These beams can support substantial weights, making them suitable for various structural applications. The exact load capacity can vary based on beam dimensions, material used, and the method of installation.

Advantages of H20 Beams

h20 beam specifications factory

1. Structural Efficiency The design of the H20 beam allows it to support heavy loads while maintaining a relatively lightweight profile. This efficiency minimizes the amount of material required for construction, leading to cost savings in materials and labor.

2. Versatility H20 beams are used in a variety of construction applications, from residential homes and commercial buildings to bridges and industrial structures. Their adaptability makes them a popular choice among engineers and architects.

3. Ease of Installation Due to their standardized sizes and shapes, H20 beams can be prefabricated and transported easily to construction sites. Their uniformity simplifies the installation process, further saving time and costs.

4. Longevity Steel beams resist many environmental factors that can lead to deterioration, such as moisture and pests. When properly maintained, H20 beams can provide a strong and stable framework for decades.

Applications

H20 beams are employed in various structural frameworks where load-bearing capabilities are critical. Some common applications include

- Residential Construction Used as floor beams in multi-story buildings, providing the necessary support for upper levels. - Commercial Buildings Serving as structural components in office buildings, shopping centers, and warehouses. - Bridges Providing the necessary strength and stability to withstand traffic and environmental stresses. - Industrial Machinery Used as support structures in factories and warehouses.

Conclusion

The H20 beam is an essential component in modern construction, combining strength, versatility, and efficiency to meet the demands of various projects. Understanding its specifications, advantages, and applications is vital for professionals in the engineering and construction industries. By choosing the right beam for specific needs, designers can ensure that their structures are safe, efficient, and built to last.

-

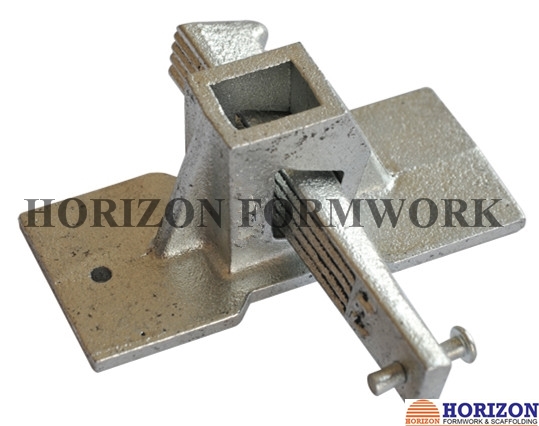

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025