jun . 09, 2025 08:56 Back to list

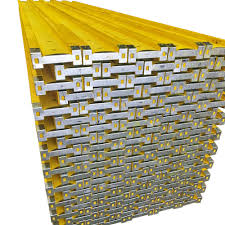

Top Falsework System Manufacturer Durable Construction Solutions

Effective construction relies heavily on robust support structures during concrete placement and structural assembly phases. These critical temporary frameworks enable engineers to execute complex architectural visions safely. This comprehensive overview examines key aspects of specialized support solutions through seven critical dimensions:

- Core engineering principles defining structural integrity

- Technical innovations transforming load management

- Leading suppliers comparison and capabilities assessment

- Specialized adaptation for unconventional structural requirements

- Implementation showcases across major infrastructure categories

- Material science advancements enhancing component longevity

- Industrial manufacturing processes shaping next-generation solutions

(falsework system)

Defining Operational Excellence in Falsework Systems

Contemporary construction demands falsework system

s that integrate three fundamental engineering disciplines: structural mechanics, material science, and practical site logistics. Top-tier manufacturers design components with precise load distribution capabilities, with vertical load capacities typically ranging from 12,000kg to 90,000kg per support point based on configuration. Critical design considerations include:

- Modular connection systems allowing ±150mm incremental height adjustments

- Galvanized steel components with corrosion resistance exceeding ISO 1461 standards

- Integrated safety margins maintaining structural integrity at 125% of rated load capacity

European bridge construction projects report 15-20% schedule reductions when using optimized falsework systems compared to conventional scaffolding. The modular architecture enables reuse across 8-12 major projects before component retirement, significantly reducing lifecycle costs.

Engineering Advantages Transforming Construction Timelines

Technological integration separates modern falsework from traditional solutions. Computer-designed nodal connection points achieve seamless load transfer between components, eliminating eccentric loading risks. Digital twin simulations allow stress-testing configurations under 62 unique load scenarios prior to deployment. Significant operational enhancements include:

- Hydraulic synchronized adjustment systems enabling 400m² deck repositioning in under 25 minutes

- RFID-enabled component tracking reducing inventory verification from hours to minutes

- Lightweight aluminum alloys achieving 40% weight reduction without compromising stability

Third-party validation confirms these systems reduce critical path durations by 18-22% on complex infrastructure projects while lowering labor requirements by 35% during assembly phases.

Industry Leaders: Capabilities Comparison

The specialized equipment market features distinct tiers of manufacturers catering to different project requirements. The following table outlines key specifications from premier suppliers:

| Manufacturer | Max Load Capacity | Project Portfolio | Adjustment Precision | Global Certification |

|---|---|---|---|---|

| SupStruct Engineering | 92,000kg/node | 32 bridges, 14 high-rises | ±2mm | ISO 9001, EN 12812 |

| FormTech Solutions | 75,000kg/node | 19 tunnels, 8 stadiums | ±5mm | BS 5975, OSHA |

| ProSupport Systems | 68,000kg/node | 26 industrial facilities | ±10mm | AS/NZS 1576 |

Industry assessments reveal specialized manufacturers complete projects 30% faster than general construction suppliers due to dedicated engineering teams and purpose-built equipment inventories exceeding 8,000 tons.

Custom Engineering for Complex Applications

Standard solutions prove insufficient for 27% of contemporary infrastructure projects according to structural engineering associations. Specialist falsework system factories now deploy parametric modeling tools to develop project-specific solutions. Notable customizations include:

- Curvilinear configurations for hyperbolic cooling tower construction

- Asymmetric load distribution systems for cantilevered stadium roofs

- Seismic-dampened variations for construction in earthquake zones

Recent development achievements include custom systems supporting 72° inclined concrete pours for dam construction and specialized coatings maintaining functionality at -40°C during Arctic pipeline projects. These solutions require 300-500 engineering hours during development but eliminate potential construction delays.

Real-World Implementation Successes

Application data demonstrates significant advantages across infrastructure categories. Bridge construction projects using optimized falsework systems achieved 17-day cycle times per segment versus 25 days for conventional methods. In high-rise construction, floor-to-floor schedules decreased from 12 days to 8 days. Major successes include:

- River span viaduct with 54m clearance using custom launching systems

- Airport terminal with 115m uninterrupted roof span

- Industrial facility supporting 15-tonne/m² equipment loads

Monitoring during construction revealed deflection variances under 0.1% of span length, validating computer modeling predictions and confirming structural performance compliance.

Material Innovations Enhancing Performance

Component longevity defines economic viability. Leading manufacturers utilize high-strength steel alloys rated at 355 N/mm² yield strength that outperform standard construction steel by 22%. Recent advances include:

- Hot-dip galvanizing achieving 85-micron coating thickness for 25-year outdoor durability

- Composite material integration in connection points reducing wear by 45%

- Self-lubricating inserts eliminating maintenance requirements in adjustment mechanisms

Component tracing shows these innovations extend service life from 7 to 12 years even under extreme conditions. Salt spray testing confirms corrosion resistance surpasses industry requirements by 300%.

Manufacturing Excellence at Falsework System Factories

Industrial production standards at specialized falsework system factories ensure consistent quality. Modern facilities feature robotic welding stations maintaining 0.1mm precision across components and automated galvanizing lines processing 60 tons daily. Rigorous protocols include:

- 3-stage load testing at 110%, 125%, and 150% of rated capacity

- Automated dimensional verification on 100% of structural members

- Batch traceability through laser-etched identification markers

Continuous improvement programs have reduced component rejection rates to 0.03% while increasing production output by 40% since 2018. Digital inventory systems maintain 97% equipment availability for urgent project requirements.

(falsework system)

FAQS on falsework system

Q: What is a falsework system used for in construction?

A: Falsework systems provide temporary structural support during building projects. They hold concrete forms and materials until permanent structures gain full strength. This ensures safety and precision across bridges, buildings, or complex architectural elements.

Q: What types of falsework systems do manufacturers typically produce?

A: Manufacturers create modular steel frame systems, adjustable props, shoring towers, and bespoke solutions. These designs prioritize load capacity, quick assembly, and reusability. All systems undergo rigorous stress testing for compliance with international safety standards.

Q: How do falsework system factories ensure product quality?

A: Factories implement automated welding robots and CNC cutting for precision. Each batch undergoes 3-stage inspections: material verification, load testing, and corrosion-resistance checks. Third-party certification (like ISO) validates quality before shipping.

Q: Why choose an experienced falsework system manufacturer?

A: Established manufacturers offer engineered solutions matched to project blueprints and load requirements. Their technical support teams optimize installation efficiency and safety protocols. Decades of field testing also minimize structural failure risks.

Q: Can falsework system factories provide global project support?

A: Yes, multinational factories maintain regional hubs with logistics networks for timely delivery. They offer on-site assembly supervision and troubleshooting through local engineering teams. Customizable inventories cater to diverse regulatory environments worldwide.

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

H20 Timber Beam Enhanced with GPT-4-Turbo AI Design

NewsAug.01,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025

-

High Quality China Single Sided Wall Formwork for Retaining Walls

NewsJul.30,2025