Nov . 19, 2024 14:30 Back to list

steel formwork details supplier

Steel Formwork Details A Comprehensive Guide for Suppliers

Steel formwork is a crucial component in modern construction, providing support and shape to concrete structures. As a supplier of steel formwork, understanding its details, applications, and benefits is essential to effectively communicate with clients and ensure successful projects. In this article, we will explore the intricacies of steel formwork, including its types, advantages, specifications, and best practices for suppliers.

Understanding Steel Formwork

Steel formwork is made from high-quality steel, designed to hold wet concrete in place until it hardens. Unlike traditional wooden forms, steel formwork boasts superior durability, strength, and reusability. It is commonly used in various construction projects, including commercial buildings, bridges, and infrastructure works.

Types of Steel Formwork

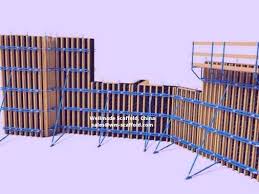

1. Modular Steel Formwork This type consists of standardized panels, making it versatile and easy to assemble. Modular systems can be adapted for different shapes and sizes, catering to specific project requirements.

2. Beam and Column Formwork Designed for pouring beams and columns, this system offers stability and support during the curing process. It typically includes vertical components, horizontal ties, and adjustable scaffolding to maintain the desired shape.

3. Climbing Formwork Ideal for high-rise construction, climbing formwork is designed to ascend as the structure grows. This system enhances productivity and safety, reducing the need for scaffolding.

4. Single-sided Formwork Used in situations where only one side of the structure needs to be formed, such as retaining walls or basements. This formwork enables efficient concrete pouring while minimizing material costs.

Advantages of Steel Formwork

- Durability Steel formwork can withstand the rigors of construction, ensuring longevity and reliability. - Reusability With proper maintenance, steel formwork can be reused multiple times, leading to cost savings for contractors and reducing waste.

- Precision Steel formwork is manufactured to tight tolerances, resulting in smooth finishes and accurate dimensions.

- Safety Steel systems provide enhanced stability, reducing the risk of accidents associated with traditional wooden forms.

- Speed The ability to quickly assemble and dismantle steel formwork leads to faster construction times, crucial for project deadlines

.steel formwork details supplier

Key Specifications to Consider

As a supplier of steel formwork, it's important to provide clients with accurate specifications to ensure their projects meet industry standards. Key specifications include

- Material Grade The steel used must comply with relevant quality standards, such as ASTM or EN, to ensure strength and performance.

- Thickness The thickness of the steel panels should be selected based on the anticipated load and project requirements.

- Surface Treatment To prevent corrosion, steel formwork should undergo surface treatments such as galvanization or painting.

- Connection Systems Understanding the various connection systems, such as clamps or bolts, is essential for ensuring stability and ease of assembly.

Best Practices for Suppliers

1. Educate Clients Provide detailed information about the advantages and applications of different types of steel formwork, helping clients make informed decisions.

2. Inventory Management Maintain a diverse inventory to meet various project requirements, including standard and custom sizes.

3. Quality Assurance Implement strict quality control measures to ensure that all steel formwork meets the specified standards and is free from defects.

4. Timely Delivery Efficient logistics and timely delivery are essential to maintaining project schedules. Invest in reliable transportation and supply chain management.

5. Customer Support Establish robust customer support to assist clients with technical inquiries and after-sales service.

Conclusion

Steel formwork is an indispensable element in contemporary construction, providing strength, precision, and efficiency. As a supplier, a deep understanding of its details, advantages, and best practices is vital to succeed in this competitive industry. By offering high-quality products, exceptional service, and expert guidance, suppliers can play a significant role in the realization of successful construction projects.

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025