Ira . 30, 2024 04:58 Back to list

Formwork Solutions for Slab Construction by Leading Exporters Worldwide

The Importance of Formwork for Slab Construction A Guide for Exporters

As the global construction industry continues to expand, the demand for high-quality formwork systems, especially for slab construction, is soaring. Exporters play a critical role in meeting this demand, providing innovative solutions that enhance efficiency, safety, and durability in construction projects. This article explores the significance of formwork for slab construction and offers insights for exporters looking to thrive in this competitive market.

Understanding Formwork in Slab Construction

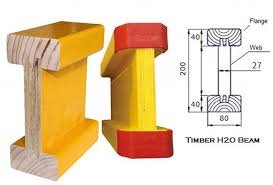

Formwork refers to the temporary structures used to support and shape concrete until it reaches the desired strength. In slab construction, formwork is essential for creating floors, ceilings, and roofs. The type of formwork used can greatly influence the project’s efficiency and quality. Traditional timber formwork has long been a standard choice, but modern advancements have led to the introduction of various materials, including steel, aluminum, and composite systems that offer greater durability and ease of use.

Key Benefits of Innovative Formwork Systems

1. Efficiency and Speed One of the primary advantages of modern formwork systems is the speed at which they can be assembled and dismantled. Modular systems allow for quicker setups, reducing the overall time needed for construction. This time-saving translates into lower labor costs and faster project completion times, which are crucial factors for contractors operating on tight schedules.

2. Cost-effectiveness While the initial investment in high-quality formwork may be higher, the long-term benefits often outweigh the costs. Durable materials require less frequent replacement, and efficient systems minimize labor costs. Furthermore, the reduced likelihood of concrete imperfections leads to fewer expenses related to repairs or rework.

3. Safety Safety is paramount in construction. Modern formwork systems often incorporate features designed to enhance safety for workers. For instance, some systems provide better access for workers and improved stability during the pouring process, reducing the risk of accidents.

4. Design Flexibility Exporters of formwork systems must also consider the varying needs of different markets. Some regions may require specialized design solutions to accommodate specific architectural styles or environmental conditions. Advanced modular formwork systems can be easily customized to meet these unique demands, making them attractive to a broad range of clients.

formwork for slab exporters

The Role of Exporters

Exporters of formwork for slab construction must focus on several key areas to succeed in the global market

1. Quality Assurance Providing high-quality products is essential for building trust and establishing a good reputation. Exporters should ensure that their formwork systems comply with international standards and undergo rigorous testing to guarantee safety and reliability.

2. Market Research Understanding the specific needs and preferences of different markets is crucial. Exporters should conduct thorough market research to identify regional demands, regulatory requirements, and competitive dynamics. Tailoring offerings to meet these needs can give exporters a significant edge.

3. Sustainable Practices With growing concerns over environmental sustainability, many construction projects now prioritize eco-friendly materials and practices. Exporters can gain a competitive advantage by offering formwork solutions that utilize sustainable materials and processes, thereby appealing to environmentally conscious clients.

4. Technical Support and Training Providing additional value through technical support and on-site training can differentiate exporters from their competitors. Ensuring that clients understand how to properly use and maintain formwork systems can enhance customer satisfaction and foster long-term relationships.

5. Building Partnerships Collaborating with local construction firms, architects, and engineers can provide exporters with insights into market trends and customer preferences. Such partnerships can also lead to joint ventures, enhancing market penetration in foreign territories.

Conclusion

The role of formwork in slab construction cannot be overstated. As the global demand for construction projects rises, the opportunity for exporters of formwork systems is immense. By focusing on quality, efficiency, and customer needs, exporters can successfully navigate the complexities of the international market and contribute to the development of safer, more efficient construction practices worldwide. As the industry evolves, those who adapt and innovate will undoubtedly lead the way in shaping the future of construction.

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025

-

China Single Sided Wall Formwork: Fast, Flexible Solutions

NewsAug.14,2025