Uzt . 31, 2024 23:18 Back to list

Innovative Formwork Solutions for Efficient Wall Production and Enhanced Manufacturing Processes

Formworks for Wall Manufacturers Streamlining Construction Processes

In today's fast-paced construction environment, the need for efficient and high-quality building processes has never been more critical. One of the pivotal elements in achieving this is the use of formworks, especially for wall manufacturers. Formwork systems are essential temporary or permanent molds used to shape and support concrete walls during the construction process. Implementing effective formwork solutions can significantly enhance productivity, safety, and the overall quality of construction projects.

Understanding Formwork Types

Formwork can be categorized into several types, including traditional timber formwork, engineered formwork systems, and modular formwork. Traditional timber formwork, while widely used, often presents challenges related to labor intensity and inconsistency in the final product. On the other hand, engineered formwork systems offer pre-manufactured solutions that can be quickly assembled and disassembled, drastically reducing construction time and labor costs. Modular formwork, composed of standardized units, allows for flexibility and adaptability on various construction sites.

Choosing the right type of formwork system is critical for wall manufacturers. The decision typically hinges on several factors, such as project specifics, budget constraints, and desired turnaround time. For instance, engineered and modular formworks may require a higher initial investment but can yield substantial savings over time through reduced labor and enhanced durability.

Benefits of Modern Formwork Solutions

1. Efficiency and Speed Modern formwork systems are designed for rapid assembly and disassembly, which significantly accelerates the construction schedule. With prefabricated components, wall manufacturers can pour concrete more quickly, leading to faster project completion and reduced overhead costs.

2. Quality Control One of the primary advantages of using engineered formwork is the consistency it brings to the construction process. With precise measurements and controlled conditions, the finished walls exhibit better surface quality and structural integrity, minimizing the need for extensive finishing work.

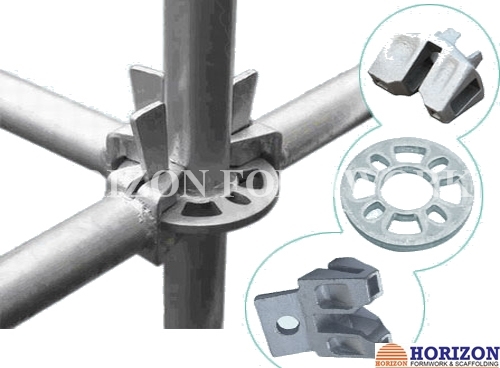

formworks for wall manufacturers

3. Safety Improvements The use of advanced formwork systems can enhance safety on construction sites. Modular and engineered formworks are designed with safety features that reduce the risk of accidents. Additionally, their lighter weight allows for safer handling by workers, minimizing potential injuries associated with heavy lifting.

4. Sustainability Environmentally conscious construction practices are becoming increasingly important. Many modern formwork solutions are made from sustainable materials and are reusable, leading to less waste generated during construction. By selecting eco-friendly formwork systems, wall manufacturers can demonstrate their commitment to sustainable building practices.

Challenges and Considerations

Despite the numerous benefits, wall manufacturers must also consider challenges associated with formwork systems. One key challenge is the initial cost, particularly with engineered or modular solutions that require upfront investment. Manufacturers must thoroughly evaluate their budget and project timelines to determine the most cost-effective solution.

Moreover, the technical knowledge required to implement and manage advanced formwork systems can be daunting. Wall manufacturers may need to invest in training for their workforce to ensure that they can effectively use and maintain these systems.

Conclusion

In conclusion, formwork systems play an integral role in the efficiency and quality of wall manufacturing within the construction industry. By embracing modern formwork solutions, manufacturers can improve their workflow, enhance safety, and produce high-quality structures while also demonstrating a commitment to sustainability. As the construction industry continues to evolve, investing in innovative formwork technologies could be the key to staying competitive in this dynamic marketplace. Wall manufacturers who adapt to these changes will not only meet the demands of today’s projects but also set the groundwork for future success.

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

H20 Timber Beam Enhanced with GPT-4-Turbo AI Design

NewsAug.01,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025

-

High Quality China Single Sided Wall Formwork for Retaining Walls

NewsJul.30,2025