helmi . 04, 2025 03:07 Back to list

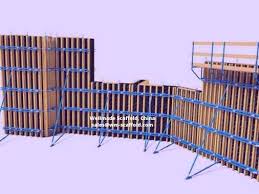

oem circular formwork columns

OEM circular concrete formwork represents an innovative solution in the construction industry, offering an efficient and cost-effective method for creating circular concrete structures. This technique has become increasingly popular due to its adaptability and precision, making it an invaluable resource for projects ranging from simple circular columns to complex architectural elements.

The authority of OEM circular concrete formwork manufacturers is often established through industry certifications and compliance with international construction standards. Adhering to rigorous testing regimes and quality assurance processes, reliable manufacturers maintain a strong reputation within the industry. Collaborative innovations and partnerships with academic institutions further enhance their authority, as research and development contribute to the evolution of superior formwork designs and techniques. Trust in OEM circular concrete formwork products is cultivated through proven performance and positive testimonials from past projects. Builders and architects often look for case studies and field reports that demonstrate successful applications in various conditions. Real-world data on durability, ease of use, and adaptability in projects help potential clients make informed decisions, reinforcing trust in the product’s promises. Ultimately, OEM circular concrete formwork has revolutionized the way circular concrete structures are built, offering a blend of technological innovation, cost-efficiency, and reliability. For construction professionals aiming to achieve excellence in their projects, understanding the nuances of this formwork system is essential. Its continued development will likely see greater adoption across industries, driven by the compelling advantages it offers in terms of speed, quality, and flexibility in the construction process.

The authority of OEM circular concrete formwork manufacturers is often established through industry certifications and compliance with international construction standards. Adhering to rigorous testing regimes and quality assurance processes, reliable manufacturers maintain a strong reputation within the industry. Collaborative innovations and partnerships with academic institutions further enhance their authority, as research and development contribute to the evolution of superior formwork designs and techniques. Trust in OEM circular concrete formwork products is cultivated through proven performance and positive testimonials from past projects. Builders and architects often look for case studies and field reports that demonstrate successful applications in various conditions. Real-world data on durability, ease of use, and adaptability in projects help potential clients make informed decisions, reinforcing trust in the product’s promises. Ultimately, OEM circular concrete formwork has revolutionized the way circular concrete structures are built, offering a blend of technological innovation, cost-efficiency, and reliability. For construction professionals aiming to achieve excellence in their projects, understanding the nuances of this formwork system is essential. Its continued development will likely see greater adoption across industries, driven by the compelling advantages it offers in terms of speed, quality, and flexibility in the construction process.

Latest news

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025