marras . 10, 2024 15:06 Back to list

Formwork Removal Techniques for Beam Construction by Leading Exporters

Removal of Formwork for Beams Best Practices and Considerations for Exporters

The construction industry is often at the forefront of innovation and efficiency, with formwork being a significant element in this process. Formwork, the temporary structure used to shape and support concrete until it hardens, plays a crucial role in building strong and durable beams. As reliance on concrete structures increases worldwide, understanding the best practices related to the removal of formwork for beams is essential for exporters in this field.

Understanding Formwork and Its Importance

Formwork has various types, including timber, steel, and plastic, each serving the specific requirements of a project. For beams, it is essential to have the formwork in place until the concrete reaches sufficient strength to support its weight and any additional loads. This process prevents structural defects and provides a smooth finish for the concrete surface.

Timing of Formwork Removal

One of the most critical factors in formwork removal is timing. Typically, formwork for beams is removed after the concrete has achieved approximately 70% of its design strength, often within 7 to 14 days, depending on the type of cement used, ambient temperature, and humidity levels. It is vital for exporters to understand the local building codes and guidelines that dictate the timing for formwork removal. Misjudging this timeframe can lead to structural issues and increased costs.

Techniques for Safe Removal

When removing formwork, safety is paramount. Exporters should ensure that their teams are adequately trained and equipped with the right tools for the job. Here are several best practices to ensure safe and efficient formwork removal

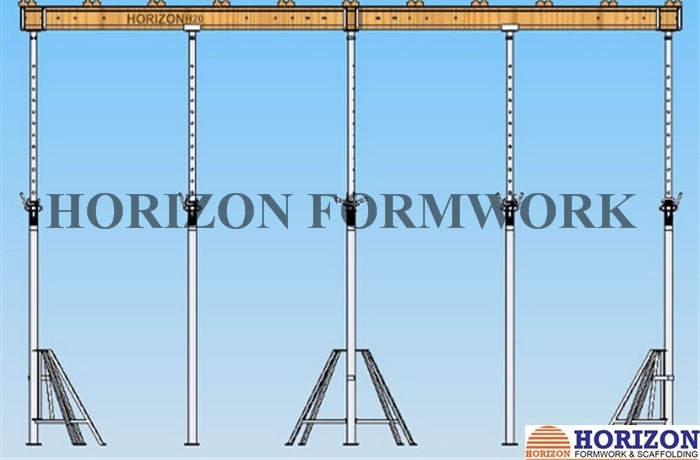

removal of formwork for beams exporters

1. Gradual Removal Start by removing the side panels and leaving the bottom formwork until the concrete has adequately cured. This gradual approach decreases the pressure on the still-soft concrete.

2. Use of Proper Tools Employ non-destructive tools designed for formwork removal to avoid damaging the concrete. Tools like pry bars and rubber mallets can help in loosening formwork without impacting the structural integrity of the beam.

3. Visual Inspection Before and after the removal process, conduct a thorough inspection of the concrete surface. Look for any signs of cracks or defects, which could indicate improper curing or removal practices.

Environmental Considerations

As sustainability becomes a priority in construction practices, exporters need to consider the environmental impact of their formwork materials. Opting for sustainable and recyclable materials can reduce waste and promote eco-friendly practices within the industry. Additionally, using reusable formwork can lead to significant cost savings over time, making it a viable option for exporters.

Conclusion A Focus on Quality and Safety

As the demand for quality construction continues to rise, understanding and implementing best practices for the removal of formwork for beams is more critical than ever for exporters. By prioritizing safety, adhering to building regulations, and considering environmental sustainability, companies can not only enhance their reputation in the market but also ensure the long-term success of their projects.

Investing in knowledge and equipment for proper formwork techniques can lead to higher quality construction, reduced labor costs, and ultimately increased customer satisfaction. By mastering these practices, exporters can better serve their clients and contribute positively to the evolving landscape of the construction industry.

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025