Nov . 06, 2024 15:17 Back to list

oem sheet pile capping beam formwork

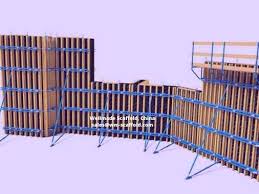

Understanding OEM Sheet Pile Capping Beam Formwork

In the realm of civil engineering and construction, the use of sheet piles and capping beams plays a crucial role in providing structural stability and support. Among the various applications of these components, the OEM (Original Equipment Manufacturer) sheet pile capping beam formwork stands out, offering innovative solutions that enhance the construction process.

What Are Sheet Piles?

Sheet piles are long, vertical sections of material that are driven into the ground to provide structural support for retaining walls, docks, and foundations. Typically made of steel or reinforced concrete, sheet piles act as barriers against soil erosion and water infiltration, making them indispensable in various construction projects. They are designed to interlock, creating a continuous barrier that can withstand lateral forces from soil and water.

The Role of Capping Beams

Capping beams are horizontal beams placed on top of vertical sheet piles. Their primary function is to distribute loads evenly across the sheet piles and provide additional stability to the structure. By connecting multiple sheet piles and transferring loads from the superstructure, capping beams help in reducing the risk of deformation and failings. They are critical in applications such as waterfront and cut-off walls, where the stability of the overall structure is paramount.

Formwork in Construction

Formwork refers to the temporary or permanent molds used to hold concrete in place as it sets. In the case of capping beams, formwork is essential for shaping the concrete, ensuring it cures correctly and achieves the desired structural properties. The formwork system must be robust enough to withstand the pressure of wet concrete while being easy to assemble and dismantle.

oem sheet pile capping beam formwork

Advantages of OEM Sheet Pile Capping Beam Formwork

1. Customization OEM sheet pile capping beam formwork can be tailored to meet specific project requirements. Manufacturers often offer solutions that align with the unique dimensions and structural needs of the project, ensuring a perfect fit.

2. Efficiency The use of OEM formwork simplifies the construction process. With pre-fabricated elements that are designed for rapid assembly, construction teams can save time on-site, reducing labor costs and project timelines.

3. Quality Assurance OEM manufacturers maintain strict quality control standards, ensuring that the materials used in the formwork are durable and reliable. This leads to enhanced performance and reduces the risk of defects in the final product.

4. Safety Properly designed formwork systems improve safety at the construction site. By providing stable, secure frameworks for pouring and curing concrete, the risk of accidents related to uncontrolled concrete flow is minimized.

5. Cost-Effectiveness While initial investments may vary, the long-term benefits of using high-quality OEM formwork include lower maintenance costs and extended lifespan of the structures.

Conclusion

The integration of OEM sheet pile capping beam formwork into construction practices not only enhances the efficiency and safety of the building process but also contributes to the overall stability and longevity of the structures. As technology continues to evolve, the future of sheet pile applications will likely see even more advanced and efficient solutions, allowing engineers and builders to tackle complex challenges with ease. Investing in high-quality OEM formwork is, therefore, a wise choice for any construction project aiming for excellence in structural performance and durability.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025