Ago . 17, 2024 02:05 Back to list

Custom Curved Concrete Formwork Solutions for Versatile Construction Applications

The Advantages of OEM Curved Concrete Formwork in Modern Construction

In the ever-evolving world of construction, innovations aimed at enhancing efficiency, durability, and aesthetic appeal are continually being developed. One such innovation is OEM (Original Equipment Manufacturer) curved concrete formwork, which has emerged as a vital solution for architects and builders striving to achieve complex designs while maintaining structural integrity. This article delves into the benefits and applications of OEM curved concrete formwork, shedding light on its significance in modern construction practices.

Understanding OEM Curved Concrete Formwork

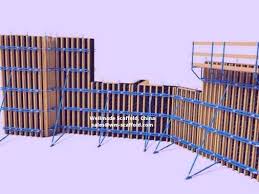

OEM curved concrete formwork refers to specialized molds designed to create curved concrete structures. These formworks are manufactured to specific requirements set by clients or designers, ensuring precision and adaptability to diverse architectural needs. Unlike traditional flat formwork, curved formwork allows for the creation of dynamic shapes and smooth surfaces that enhance the aesthetic quality of buildings, bridges, and other infrastructures.

Benefits of Using OEM Curved Concrete Formwork

1. Design Flexibility One of the primary advantages of using OEM curved concrete formwork is the flexibility it offers in architectural design. Curved structures, which were once a challenge to execute, can now be realized effortlessly. This formwork allows architects to explore creative ideas without being constrained by conventional straight lines, leading to innovative building designs that stand out in an urban landscape.

oem curved concrete formwork

2. Enhanced Aesthetics Curved designs add a unique visual appeal to structures, making them not only functional but also attractive. The smooth lines and flowing forms created by curved concrete can significantly enhance the overall aesthetics of a project, whether it's a contemporary art museum or an iconic bridge.

3. Structural Integrity OEM curved concrete formwork is engineered to ensure that the resulting structures are robust and resilient. The ability to create uniform curves enhances the distribution of stress throughout the material, contributing to the structural stability of the building. As a result, these structures can withstand various environmental loads and challenges.

4. Time and Cost Efficiency While the initial investment in OEM curved formwork may be higher than traditional methods, the long-term benefits often outweigh these costs. The precise manufacturing of formwork reduces the time required for installation and concrete pouring, resulting in shorter project timelines. Furthermore, the durability and reduced maintenance requirements of curved structures can lead to significant cost savings over time.

5. Sustainability As the construction industry shifts towards more sustainable practices, OEM curved concrete formwork offers a path forward. The reduced material waste during the construction process, coupled with the longevity of the structures built with this formwork, aligns with sustainability goals. Additionally, the energy efficiency of buildings can be enhanced through innovative designs that utilize natural light and air flow.

Conclusion

The advent of OEM curved concrete formwork represents a significant leap forward in construction technology. Its ability to merge functionality with innovative design opens up new possibilities for architects and builders, allowing them to create structures that are not only visually stunning but also structurally sound and sustainable. As the demand for unique and high-quality construction continues to grow, OEM curved concrete formwork will undoubtedly play a pivotal role in shaping the future of the industry. Embracing this technology will enable stakeholders to push the boundaries of design and engineering, resulting in a built environment that reflects creativity, efficiency, and resilience.

-

Premium H20 Timber Beams | Durable Structural Solutions

NewsAug.05,2025

-

Premium Wall Formwork Solutions for Modern Construction

NewsAug.03,2025

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025