સપ્ટેમ્બર . 28, 2024 04:56 Back to list

Formwork Solutions for Efficient Beam and Slab Production in Factories

Formwork for Beam and Slab Factories

In the construction industry, formwork plays a pivotal role in shaping concrete structures, and it is especially crucial in beam and slab factories. These factories focus on prefabricating concrete elements, and the right formwork is essential for ensuring efficiency, quality, and safety during production. This article explores the importance of formwork in beam and slab factories, the types of formwork available, and recent advancements in formwork technology.

Formwork for Beam and Slab Factories

There are several types of formwork used in beam and slab production. Traditional timber formwork is one of the oldest methods, offering flexibility and ease of use. However, it often lacks durability and may require additional labor for setup and dismantling. As an alternative, steel formwork is gaining popularity due to its longevity and ability to produce smoother finishes with less maintenance over time. Moreover, aluminum formwork has emerged as a lightweight yet robust option, reducing transportation costs, labor, and time on-site.

formwork for beam and slab factories

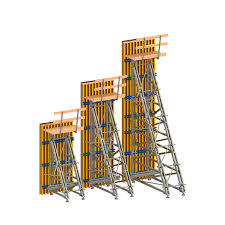

Innovative formwork solutions, such as modular and climbing formwork systems, are transforming how beam and slab factories operate. Modular systems consist of prefabricated panels that can be easily assembled and disassembled, making them ideal for repetitive tasks involved in factory settings. Climbing formwork, on the other hand, allows for vertical construction of elements in a sequential manner, enhancing productivity and reducing the risk of delays.

Safety is another critical consideration in formwork design. Beam and slab factories must adhere to stringent safety regulations to protect workers. Recent advancements in formwork technology have led to the development of systems that enhance safety features, such as integrated safety barriers and improved load distribution. These innovations not only minimize the risk of accidents but also optimize productivity by allowing workers to focus on their tasks without the constant concern for safety.

Furthermore, sustainability is increasingly becoming a factor in the choice of formwork materials in beam and slab factories. Eco-friendly formwork options that are reusable or recyclable are gaining traction, aligning with broader industry efforts to reduce waste and environmental impact. Manufacturers are creating formwork from sustainable materials, thereby contributing to energy and material efficiency in the construction process.

In conclusion, formwork is a vital component in the operation of beam and slab factories. The type of formwork chosen can significantly influence the quality of the concrete products, production efficiency, and safety standards. With the continuous evolution of formwork technology, factories are now better equipped to produce high-quality concrete elements that meet the demands of modern construction. As the industry moves towards greater sustainability, the development of innovative, eco-friendly formwork solutions will likely play a crucial role in shaping the future of construction. Ultimately, investing in the right formwork system can lead to enhanced productivity and results, ensuring that beam and slab factories remain at the forefront of the construction sector.

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025