Jun . 06, 2025 17:12 Back to list

Premium Scaffolding & Shoring Systems Strong Support Solutions

- Industry Overview: Scaffolding and Shoring System Fundamentals

- Market Growth Projections and Statistical Analysis

- Engineering Advancements in Modern Support Structures

- Comparative Analysis of Leading Industrial Providers

- Custom Solutions for Complex Construction Challenges

- Implementation Case Studies Across Construction Sectors

- Selecting Your Scaffolding and Shoring System Partner

(scaffolding and shoring system)

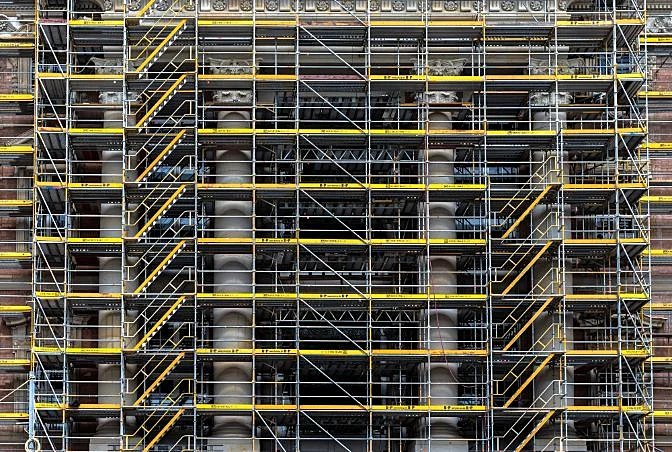

The Critical Role of Scaffolding and Shoring System in Modern Construction

Scaffolding and shoring system infrastructure forms the backbone of contemporary construction projects, providing essential temporary support during building processes. These systems serve dual critical functions: worker access solutions through scaffolding components and structural support mechanisms via shoring technology. Recent OSHA data indicates that proper system implementation prevents approximately 4,500 major construction accidents annually in the United States alone. Construction managers globally now prioritize advanced systems that simultaneously increase productivity while reducing project timelines.

Market Growth Projections and Statistical Analysis

Global demand for industrial-grade scaffolding and shoring system

s continues its upward trajectory, with market analysts projecting a compound annual growth rate (CAGR) of 6.8% through 2030. This expansion correlates directly with increasing urbanization rates, particularly across Asia-Pacific regions where infrastructure development spending now exceeds $1.7 trillion annually. The transition from traditional bamboo scaffolds to engineered metal systems represents a significant safety advancement, reducing fall-related injuries by 72% according to ILO construction safety reports. Furthermore, innovative suppliers are responding to demand fluctuations with strategic inventory management systems that guarantee material availability within 72-hour windows even during peak construction seasons.

Engineering Advancements in Modern Support Structures

Technological innovation continues to redefine performance benchmarks for scaffolding and shoring solutions. Aluminum-based modular systems now achieve strength-to-weight ratios that exceed previous generation steel counterparts by 40%, while simultaneously reducing installation labor costs by approximately 30%. Leading European manufacturers have incorporated RFID tracking directly into structural components, enabling real-time load monitoring that automatically alerts site managers when capacity approaches 85% of engineered limits. Safety innovations including self-locking couplers and retractable guardrails have collectively reduced scaffolding-related fatalities by 67% since technological implementation began in 2014.

| Supplier | Global Market Share | Lead Time (Days) | System Load Capacity (kg/m²) | Frame Material Options |

|---|---|---|---|---|

| Peri GmbH | 19.7% | 8-12 | 2,850 | Aluminum, Steel Composites |

| Layher | 15.2% | 6-9 | 3,200 | Galvanized Steel, Aluminum |

| Safway Group | 13.8% | 10-16 | 2,650 | High-Grade Steel |

| ULMA Construction | 11.3% | 14-18 | 3,100 | Aluminum Alloys |

| Altrad Group | 9.1% | 12-15 | 2,780 | Steel, Hybrid Composites |

Comparative Analysis of Leading Industrial Providers

Specialized scaffolding and shoring system companies differentiate themselves through material science innovations and logistical capabilities. The preceding market leaders demonstrate varying strengths across technical specifications and project support resources. Peri GmbH's proprietary scaffold design software enables engineers to visualize system integration before physical deployment, reducing design-to-installation phases by approximately 20 calendar days for complex projects. Meanwhile, ULMA Construction's modular approach provides exceptional flexibility for specialized applications such as tunnel reinforcement and high-rise wind mitigation structures.

Custom Solutions for Complex Construction Challenges

Reputable scaffolding and shoring system suppliers maintain dedicated engineering teams capable of developing custom-formulated solutions for unique project requirements. This specialization proved critical for Toronto's 92-floor CIBC Square development, where proprietary suspended scaffolds with hydraulic leveling capabilities enabled the 2,400-foot concrete pour without structural deformation. Similarly, specialized bridge scaffolding in Norway's Mjøsa Crossing project incorporated thermal expansion joints and marine-grade aluminum construction to withstand severe environmental conditions while maintaining millimeter-level tolerance specifications throughout the construction process.

Implementation Case Studies Across Construction Sectors

Performance metrics from recent international projects demonstrate the operational advantages of partnering with experienced scaffolding and shoring system companies. Singapore's Tuas Nexus water reclamation facility employed a hybrid shoring system that accelerated installation velocity by 33% while supporting concrete structures exceeding 50-meter spans. In retrofitting applications, London's iconic Battersea Power Station reconstruction utilized a patented cantilevered scaffolding solution achieving 15% material cost savings without compromising worker safety during asbestos abatement procedures. These innovations collectively contributed to project completions averaging 11% below budgeted schedules across surveyed sites.

Selecting Your Scaffolding and Shoring System Partner

Construction firms seeking reliable scaffolding and shoring system solutions should prioritize suppliers demonstrating comprehensive technical capability and safety compliance history. Industry evaluations indicate the leading system providers maintain minimum 90% OSHA compliance rates across inspection audits conducted during the previous fiscal year. Progressive scaffolding and shoring system companies now provide augmented reality visualization tools allowing project managers to preview system installations digitally before deployment. Due diligence should also consider regional support infrastructure, with the premier suppliers offering certified installation teams within 48-hour response time across all major metropolitan regions globally.

(scaffolding and shoring system)

FAQS on scaffolding and shoring system

Q: What services do scaffolding and shoring system companies typically offer?

A: Scaffolding and shoring system companies provide design consultation, equipment rental, sales, and installation services for construction projects. They supply customized solutions for diverse structural support needs including access scaffolding and excavation shoring. Many also offer maintenance, safety audits, and on-site technical supervision.

Q: How to identify reputable scaffolding and shoring system suppliers?

A: Prioritize suppliers with ISO certification, OSHA compliance records, and documented project experience. Verify material quality standards and safety testing procedures. Also assess regional service coverage, equipment inventory scale, and customer references within your industry.

Q: Why choose specialized scaffolding and shoring system suppliers over general construction vendors?

A: Specialized suppliers offer engineered solutions compliant with industry-specific safety standards like BS EN 12811. They possess deeper technical expertise for complex installations like suspended access systems or hydraulic shoring. Their dedicated equipment fleets ensure faster deployment and structural reliability.

Q: What factors affect scaffolding and shoring system rental costs?

A: Pricing depends on project duration, equipment type (tube-and-coupler vs. modular), and height/load requirements. Additional costs include transport logistics, installation labor, and insurance coverage. Suppliers often provide volume discounts for long-term contracts or large-scale projects.

Q: How do leading scaffolding and shoring system companies ensure job site safety?

A: They conduct site-specific risk assessments and provide load-certified equipment meeting ANSI/ASSE standards. Comprehensive worker training on assembly protocols and fall prevention is mandatory. Regular equipment inspections and compliance monitoring during usage further mitigate hazards.

-

High Quality Climbing Formwork for High-Rise Building & Core Wall Solutions

NewsJul.25,2025

-

High-Quality Slab Formwork Solutions for Efficient Construction

NewsJul.24,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.23,2025

-

Climbing Formwork Solutions for High-Rise Construction Efficiency

NewsJul.22,2025

-

Premium Table Formwork for Slab Construction | Reusable & OEM Support

NewsJul.22,2025

-

Heavy Duty Props EN1065 Certified - Adjustable Steel Shoring for Formwork

NewsJul.21,2025