ספט . 22, 2024 21:36 Back to list

oem steel formwork construction

The Role of OEM Steel Formwork in Modern Construction

In the ever-evolving world of construction, efficiency and quality are paramount. One of the innovations that have significantly contributed to enhancing these aspects is the use of OEM (Original Equipment Manufacturer) steel formwork. This construction method has revolutionized how structures are built, offering numerous advantages that cater to the demands of modern architecture and engineering.

The Role of OEM Steel Formwork in Modern Construction

One of the primary benefits of using OEM steel formwork is its ability to improve construction speed. Since these formworks are prefabricated, they can be assembled quickly on-site, significantly reducing the time required for construction. In a world where time is money, this efficiency not only accelerates project delivery but also minimizes labor costs. The lightweight nature of steel formwork, combined with its simple assembly design, allows crews to work faster and more effectively.

oem steel formwork construction

Moreover, the precision of OEM steel formwork leads to improved quality of finished products. Steel formwork systems are engineered to exact specifications, ensuring that every pour of concrete results in consistent and reliable results. This uniformity eliminates the irregularities often seen when using traditional materials, ultimately leading to stronger and more durable structures. Architects and engineers can also rely on steel formwork to achieve intricate designs and configurations that might be difficult or impossible with other materials.

Another significant aspect of OEM steel formwork is its environmentally friendly nature. Steel is a highly recyclable material, and the use of steel formwork significantly reduces waste associated with the construction process. Traditional wooden formworks often require cutting down trees for material, which contributes to deforestation. In contrast, steel formwork systems can be reused multiple times, diminishing the need for new resources and contributing to a more sustainable building approach.

Furthermore, OEM manufacturers often offer custom solutions tailored to the specific needs of a project. This adaptability is crucial in an industry where unique designs and local regulations can pose challenges. Manufacturers work closely with construction companies to provide tailored solutions that ensure compliance while meeting performance expectations.

In conclusion, the adoption of OEM steel formwork in construction represents a paradigm shift towards greater efficiency, quality, and sustainability. By integrating this advanced formwork system, construction companies can enhance their operational capabilities, reduce their environmental footprint, and deliver superior projects within tighter timelines. As the construction industry continues to innovate, OEM steel formwork is sure to play a pivotal role in shaping the future of building practices, enabling more complex and ambitious projects while maintaining focus on efficiency and sustainability.

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

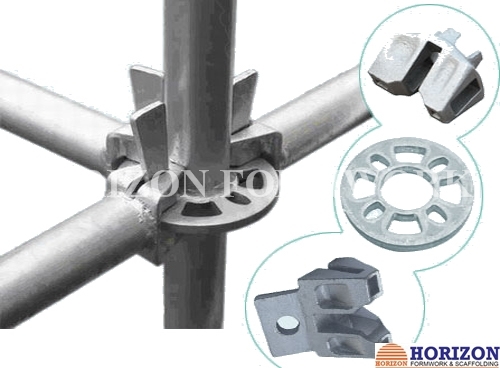

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025