-

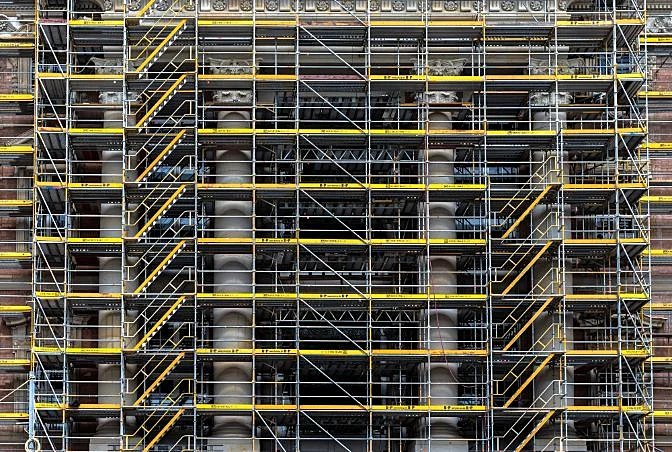

The Different Types of Scaffolding Used in Construction Scaffolding

Scaffolding, also known as staging, is a temporary provisional framework used in construction sites to provide support to the buildings’ original structure.Read more -

Different Types of Scaffolding in Construction Scaffolding

An undeniably integral part of most construction projects when working at height, scaffolding has been used for hundreds of years and surprisingly little has changed since the first scaffolding rigs were first built from wood and bamboo.Read more -

HOW SCAFFOLDING IS USED IN CONSTRUCTION Scaffolding

A scaffold, also known as staging, provides temporary support to the original structure of a building during construction. The scaffolding also provides a platform for crew members to perform construction work at heights they would not otherwise be able to reach.Read more -

WHY SCAFFOLDING IS IMPORTANT DURING CONSTRUCTION Scaffolding

If you picture a construction site, you are more than likely going to conjure up an image of a half-finished building with a number of workers navigating themselves around a tall, steel structure. This structure, commonly known as scaffolding, is one of the most familiar aspects of any architectural job, but why is this aspect of construction so vital?Read more -

THE COMPLETE GUIDE TO SCAFFOLDING Scaffolding

Picture a construction site and you’ll likely conjure up an image of a half-finished building surrounded by a tall, steel structure. This structure is commonly referred to as scaffolding, and it is an essential component of construction, ensuring workers can operate safely and build efficiently.Read more -

What Is Scaffolding? Scaffolding

Scaffolding is a temporary structure that is typically made from metal poles and wood planks and used to support construction workers, inspectors, cleaners, and others who need to work at height.Read more -

Types of Scaffolds Scaffolding

Scaffolds are temporary structures built to help reach work areas that are well above ground level. Scaffolds can also be constructed as access platforms. According to the Occupational Health and Safety Administration (OSHA); a scaffold is “an elevated, temporary work platform” (n.d).Read more -

WHAT ARE THE 3 MAIN TYPES OF SCAFFOLDS? Scaffolding

According to a study published in 2022, scaffolding is worth £2.86 billion to the UK economy. At the time, the Construction Industry Training Board (CITB) forecasted that 200 scaffolding professionals would be needed every year to meet construction demands; this number has significantly increased since then.Read more -

What are the Three Main Types of Scaffolding Solutions? Scaffolding

Working above ground on a building project requires scaffolding solutions, as without them, it would not only be impractical but also extremely dangerous to complete a build. The construction of the scaffolding that needs to be used is completely dependent on the project that is being undertaken.Read more -

What Are the Three Main Types of Scaffolding? Scaffolding

Most construction jobs require scaffolding, whether the work involves repair, improvement, demolition or new building. Working above ground-level without it would be not only impractical, but also unacceptably dangerous. There are numerous types of scaffolding.Read more -

The Three Main Categories of Scaffolding Scaffolding

If you are a layman or you're just starting in construction, you might assume scaffolding is all the same - in some way that's correct. Scaffolding hasn't changed much in the millennia since it was first created, relying on the same underlying principles. However, amongst this terrain of bars and bolts, there is a surprising amount of variety.Read more -

How to become a formworker

There are several routes to becoming a formworker. You could do a college course, an apprenticeship, or on the job training by applying to an employer directly. You should explore these routes to find out which is the right one for you. Although some of these options have certain qualification requirements, many employers are more interested in people who are enthusiastic, willing to learn and can follow instructions.You may need a Construction Skills Certification Scheme (CSCS) card to work on a construction site.Read more