Dec . 11, 2024 02:41 Back to list

Concrete Formwork Solutions for Efficient Slab Production in Manufacturing Facilities

The Importance of Concrete Formwork in Slab Construction

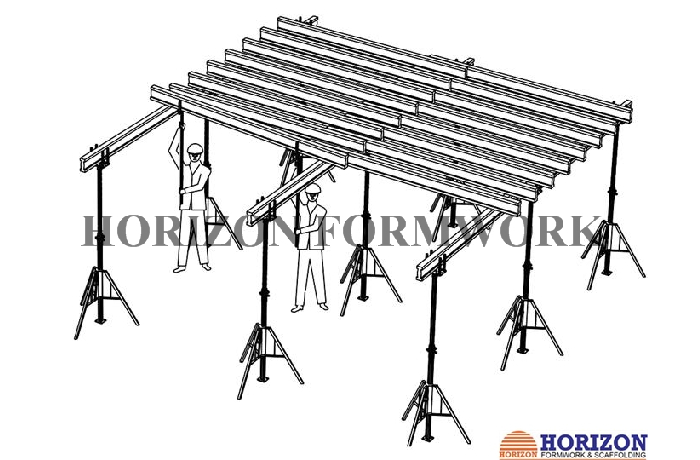

Concrete formwork is a crucial component in the construction industry, particularly in the creation of slabs. It serves as a mold or frame that holds concrete in place while it cures, shaping the final structure. The efficiency and effectiveness of formwork significantly impact the overall quality and durability of concrete slabs, making it an essential consideration for contractors and builders.

Understanding Concrete Formwork

Formwork can be made from various materials, including wood, steel, aluminum, and plastic. Each material has its unique advantages and applications. For instance, wooden formwork is widely used due to its flexibility and ease of construction, while steel formwork is preferred for its durability and the ability to produce smooth finishes. Aluminum formwork is lightweight and offers high reusability, making it cost-effective for large projects.

In the context of slab construction, formwork is designed to accommodate the specific dimensions, load requirements, and architectural features dictated by the project. Properly engineered formwork ensures that concrete is poured and set in the desired shape and alignment, leading to structurally sound slabs.

The Role of Formwork in Slab Quality

The quality of concrete slabs is directly influenced by the formwork system employed. Well-designed formwork can contribute to reducing the likelihood of defects such as cracking, warping, or shrinkage. It also allows for better control of concrete placement, ensuring that it fills the mold completely and uniformly.

concrete formwork slabs factories

Moreover, formwork can facilitate the inclusion of reinforcing materials, such as rebar, which enhances the tensile strength of the slab. Adequate support provided by formwork during the curing process is vital, as it prevents sagging or deformation of the wet concrete.

Speed and Efficiency in Construction

In today's fast-paced construction environment, time is of the essence. Modern formwork systems, particularly those that are modular or engineered for rapid assembly, can significantly reduce construction time. Prefabricated formwork can be quickly erected and dismantled, allowing more rapid turnover of construction sites. This not only accelerates project timelines but also reduces labor costs, making it more efficient for builders.

Sustainability Considerations

As environmental concerns grow, the construction industry is increasingly seeking sustainable practices. Formwork systems that emphasize reusability and recyclability can greatly reduce waste. For example, aluminum and steel forms can be used multiple times before needing replacement, significantly decreasing material consumption. Additionally, advancements in formwork technology have led to the development of eco-friendly materials that reduce the carbon footprint associated with construction practices.

Conclusion

In conclusion, concrete formwork plays a vital role in the construction of slabs, impacting the quality, efficiency, and sustainability of projects across the industry. Selecting the right formwork system tailored to specific project requirements is essential for achieving high-performance concrete structures. As construction practices evolve, continued emphasis on innovative formwork solutions will be fundamental to meeting both industry demands and environmental responsibilities. By investing in quality formwork, builders can ensure that they achieve not only functional but also resilient and sustainable concrete slabs that stand the test of time. Thus, embracing the advancements in formwork design and materials is not just beneficial; it is essential for the future of construction.

-

Advanced Column Formwork with GPT-4 Turbo | Efficient Construction

NewsAug.04,2025

-

Premium Wall Formwork Solutions for Modern Construction

NewsAug.03,2025

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

H20 Timber Beam Enhanced with GPT-4-Turbo AI Design

NewsAug.01,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025