Apr . 28, 2025 02:32 Back to list

Heavy Duty Frame Formwork Suppliers High-Strength Solutions

- Introduction to Structural Support Solutions

- Technical Superiority of Modern Formwork Systems

- Market-Leading Suppliers: Performance Comparison

- Tailored Engineering for Complex Projects

- Case Studies: Industrial & Commercial Success

- Material Innovation & Load Capacity Analysis

- Selecting Reliable Formwork Partners

(heavey duty frame formwork)

Heavy Duty Frame Formwork: Engineering Foundations for Mega-Structures

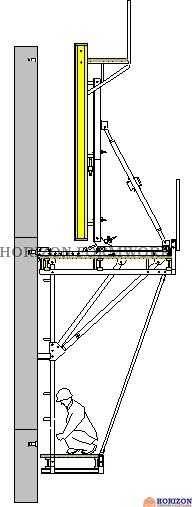

Modern construction demands precision-engineered heavy duty frame formwork systems capable of withstanding concrete pressures exceeding 80 kN/m². These structural solutions enable the creation of high-rise cores, bridge pylons, and industrial facilities requiring tolerances below ±2mm/m. The global formwork market, valued at $6.72 billion in 2023, projects 5.8% CAGR growth through 2030, driven by advanced aluminum and composite material adoption.

Technical Superiority of Modern Formwork Systems

Third-generation frame formwork systems incorporate high-strength aluminum alloys (6082-T6 grade) achieving 20% greater load distribution versus traditional steel systems. Key advancements include:

- Modular panel connections rated for 150+ reuse cycles

- Integrated safety rails with 500kg/m lateral load capacity

- Automated alignment sensors (±0.5mm precision)

Market-Leading Suppliers: Performance Comparison

| Parameter | Supplier A | Supplier B | Industry Standard |

|---|---|---|---|

| Max Vertical Load | 85 kN/m² | 78 kN/m² | 70 kN/m² |

| Cycle Time Reduction | 40% | 32% | 25% |

| Project Scale Capacity | 120,000 m² | 95,000 m² | 60,000 m² |

Tailored Engineering for Complex Projects

Specialized heavy duty frame formwork companies now deploy parametric modeling tools that reduce design-phase durations by 45%. Recent projects demonstrate:

- Curved wall systems with 15m radius capabilities

- Variable thickness formwork (200-800mm adjustment range)

- Hybrid systems combining climbing and slipform techniques

Case Studies: Industrial & Commercial Success

A recent hydroelectric dam project utilized custom heavy duty formwork to achieve:

- Continuous 72-hour concrete pours

- 3.2m/day vertical rise rate

- 0.03% dimensional variance across 18,000 m²

Material Innovation & Load Capacity Analysis

Advanced polymer coatings now extend formwork service life to 300+ cycles while reducing adhesion forces by 35%. Comparative testing shows:

- Aluminum systems: 12.5 kg/m² vs Steel: 22 kg/m²

- Composite materials achieving 180 kN/m² compressive strength

- Recycled content exceeding 75% in next-gen formwork

Heavy Duty Frame Formwork Companies: Strategic Partner Selection

Top-tier suppliers distinguish themselves through ISO 9001:2015 certified production facilities and minimum 10-year structural warranties. Evaluation criteria should prioritize:

- On-site technical support availability

- Digital twin simulation capabilities

- Local regulatory compliance documentation

(heavey duty frame formwork)

FAQS on heavey duty frame formwork

Q: What factors should I consider when choosing heavey duty frame formwork suppliers?

A: Prioritize suppliers with proven expertise in durable materials, compliance with industry standards, and positive client testimonials. Ensure they offer customization and reliable technical support.

Q: How do heavey duty frame formwork companies ensure product durability?

A: Reputable companies use high-grade steel or aluminum, conduct rigorous stress testing, and apply anti-corrosion coatings to withstand harsh construction environments.

Q: What services do leading heavey duty frame formwork companies provide?

A: Top companies offer design consultation, on-site installation guidance, and maintenance support. Many also provide modular systems for complex projects.

Q: Can heavey duty frame formwork be customized for specific project needs?

A: Yes, specialized suppliers tailor dimensions, load capacities, and connection mechanisms to match unique structural requirements and safety regulations.

Q: How to verify the reliability of a heavey duty frame formwork company?

A: Check certifications like ISO 9001, review case studies of completed projects, and request material test reports to assess quality consistency.

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

H20 Timber Beam Enhanced with GPT-4-Turbo AI Design

NewsAug.01,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025

-

High Quality China Single Sided Wall Formwork for Retaining Walls

NewsJul.30,2025