Dec . 14, 2024 09:45 Back to list

Exporters of Climbing System Formwork Solutions for Construction Projects Worldwide

Climbing System Formwork Exporters Revolutionizing Construction Practices

In the realm of modern construction, efficiency and safety are paramount. Among the various advancements in construction technology, climbing system formwork has emerged as a game-changer. Formwork systems are temporary or permanent molds into which concrete is poured to form structural elements. Climbing system formwork takes this a step further by allowing the formwork to ascend as construction progresses, providing significant advantages over traditional methods. This technological advancement has opened new avenues for exporters in the construction industry, ensuring that projects are completed more swiftly and safely.

The Climbing System Formwork Explained

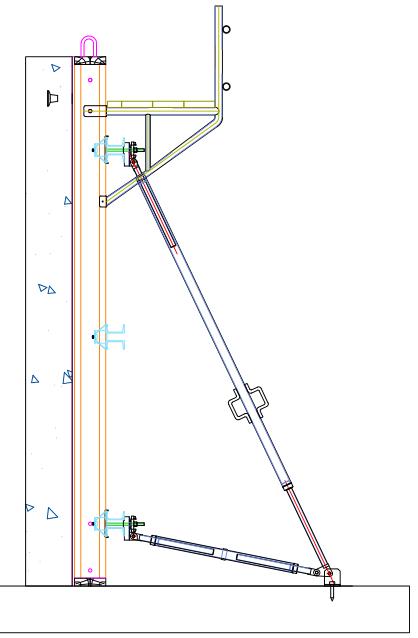

At its core, climbing formwork is designed to support the vertical construction of structures like high-rise buildings, bridges, and towers. This innovative system can be moved upward at specific intervals, eliminating the need for scaffolding and reducing the labor costs associated with formwork erection and dismantlement. The system is typically anchored to the structure being built, allowing the formwork to be lifted progressively as the concrete sets.

This approach not only enhances safety but also increases the pace at which a structure can be erected. With climbing formwork, workers can complete the pouring of concrete floors, walls, and other elements without the delays often associated with traditional formwork systems. Furthermore, the precision of climbing formwork contributes to better finishes, reducing the need for additional reinforcing or repairs later in the construction process.

The Rise of Climbing System Formwork Exporters

As the demand for high-rise and complex structures continues to grow worldwide, so too does the demand for advanced construction technologies like climbing system formwork. Exporters are taking note of this trend and are strategically positioning themselves in global markets. Countries with burgeoning construction industries, such as India, China, and various nations in the Middle East, are particularly attractive for exporters looking to supply climbing system formwork.

climbing system formwork exporters

Success in this niche market hinges on a few key factors. First and foremost, quality is critical. The materials used in climbing system formwork must meet rigorous safety standards to withstand the pressures of concrete pouring and the stresses of vertical construction. Exporters that prioritize high-quality materials and manufacturing processes are more likely to establish a strong reputation and gain a competitive edge in the market.

Another significant factor is the emphasis on customization. Each construction project is unique, requiring tailored solutions to meet specific needs. Exporters that can offer bespoke formwork solutions, including design modifications and adaptable systems, can cater to a wider array of projects, thereby expanding their market reach.

Sustainability and Innovation in Climbing System Formwork

The construction industry is increasingly focusing on sustainability, and climbing system formwork is no exception. Many exporters are integrating environmentally friendly practices into their operations, including the use of recycled materials and energy-efficient manufacturing processes. Additionally, the efficiency of climbing formwork can contribute to reducing the overall carbon footprint of construction projects by minimizing waste and conserving resources.

Innovation plays a critical role in maintaining competitiveness in this market. Exporters are exploring advanced technologies such as automated systems and smart monitoring solutions that can enhance the functionality and safety of climbing formwork. By investing in research and development, exporters can stay ahead of industry trends and continue to deliver cutting-edge solutions to their clients.

Conclusion

The climb towards modern construction practices is marked by the advent of climbing system formwork, which offers unparalleled efficiency, safety, and quality. As the global construction sector continues to evolve, climbing system formwork exporters are well-positioned to meet the increasing demands for advanced, customizable, and sustainable solutions. By prioritizing quality and innovation, these exporters are not just building structures; they are contributing to the future of construction, one climb at a time. As the construction industry embraces these advancements, the role of climbing system formwork will undoubtedly expand, paving the way for more ambitious architectural endeavors across the globe.

-

Premium Table Formwork for Slab Construction | Reusable & OEM Support

NewsJul.22,2025

-

Heavy Duty Props EN1065 Certified - Adjustable Steel Shoring for Formwork

NewsJul.21,2025

-

Heavy Duty Tripod & Fork Head: Stable Camera Mount for Pro Shots

NewsJul.21,2025

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025