Dic . 05, 2024 15:08 Back to list

light duty frame formwork factory

Understanding Light Duty Frame Formwork An Insight into Its Production and Applications

In the ever-evolving construction industry, efficiency and durability are key factors that influence the choice of materials and methods employed in projects. One of the significant innovations that have emerged in recent years is light duty frame formwork. This type of formwork is revolutionizing the way construction professionals approach building processes, offering a blend of strength, flexibility, and ease of use. In this article, we will explore the characteristics, benefits, and production processes associated with light duty frame formwork, shedding light on why it has become a preferred option for many construction projects.

What is Light Duty Frame Formwork?

Light duty frame formwork refers to a temporary structure designed to hold concrete in place while it sets. Unlike traditional scaffolding, this formwork typically utilizes lighter materials that allow for easier handling and installation, making it suitable for a variety of applications, including residential buildings, commercial projects, and infrastructure works.

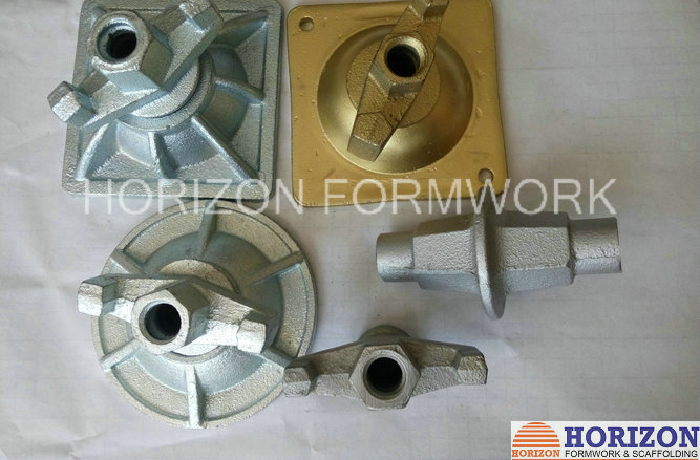

The primary components of light duty frame formwork include frames, panels, and connectors. The frames are made from high-strength steel or aluminum, providing robust support while ensuring reduced weight for ease of use. The panels are often plywood or steel-faced, designed to withstand the pressure exerted by freshly poured concrete. This modular system allows for quick assembly and disassembly, which is essential in meeting tight project timelines.

Benefits of Light Duty Frame Formwork

1. Ease of Handling and Installation Given their lightweight design, light duty frame formworks can be easily transported and installed by fewer workers. This translates into lower labor costs and increased productivity on site. The intuitive design also enables quicker assembly and disassembly, further enhancing operational efficiency.

2. Versatility This type of formwork can be used in various applications—whether for walls, slabs, or columns. Its modular nature allows for easy adaptation to different construction needs, making it a versatile choice for contractors.

3. Cost-Effectiveness While the initial investment in formwork might seem high, the long-term savings associated with light duty frame formwork are significant. Its durability leads to lesser repair costs, and the speed of installation allows for faster project completion, enabling contractors to take on more projects within the same timeframe.

4. Environmentally Friendly With an increasing emphasis on sustainable construction practices, light duty frame formwork aligns well with eco-friendly initiatives. Many manufacturers use recyclable materials and designs that minimize waste, contributing to a greener construction process.

light duty frame formwork factory

Production Process of Light Duty Frame Formwork

The production of light duty frame formwork involves several critical steps to ensure quality and performance

1. Material Selection Quality begins with the right materials. Manufacturers typically select high-strength steel or aluminum for frames and durable plywood or steel for panels. The selection is based on balancing weight, strength, and cost.

2. Design and Engineering Engineers collaborate with design teams to create formwork systems that can withstand specific loads and pressures based on project requirements. This phase includes detailed schematics and prototype testing.

3. Manufacturing Advanced machinery and technology are employed to fabricate the components of light duty frame formwork. This includes cutting, welding, and finishing processes that adhere to strict industry standards.

4. Quality Control Before the products are shipped, they undergo rigorous quality control tests to ensure they meet safety and performance criteria. This step is vital to maintaining the reputation of the manufacturer and the safety of construction workers.

5. Logistics and Distribution Once completed, the formwork is packaged and transported to construction sites. Efficient logistics are essential to ensure timely delivery, preventing project delays.

Conclusion

Light duty frame formwork represents a significant advancement in construction methodologies. Its lightweight nature, combined with strength and versatility, is making it a go-to solution for many contractors seeking efficiency and cost-effectiveness. As the construction industry continues to embrace innovation, the popularity of light duty frame formwork is likely to rise, solidifying its place within modern construction practices. With a focus on quality production processes and sustainability, manufacturers are poised to play an integral role in shaping the future of construction.

-

Durable Steel Prop with Tripod for Stable Support

NewsAug.10,2025

-

OEM Column Formwork: Custom, Circular, Curved & Adjustable

NewsAug.09,2025

-

Custom OEM Column Formwork | Versatile & Efficient Solutions

NewsAug.08,2025

-

Steel Prop with Tripod & Fork Head | Stable Support Solutions

NewsAug.07,2025

-

Premium H20 Timber Beams | Durable Structural Solutions

NewsAug.05,2025

-

Premium Wall Formwork Solutions for Modern Construction

NewsAug.03,2025