9月 . 22, 2024 00:26 Back to list

formwork wing nut factory

The Importance of Formwork Wing Nuts in Construction

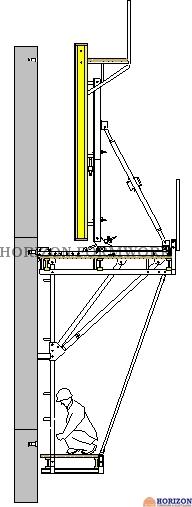

Formwork wing nuts are critical components in the construction industry, playing a vital role in the assembly and stability of formwork systems. These nuts are designed to secure the formwork panels together, ensuring they remain in place while concrete is poured and cured. Understanding the significance of wing nuts, alongside their production processes at factories, highlights their contribution to the efficiency and safety of construction projects.

What are Formwork Wing Nuts?

Formwork wing nuts are specifically designed nuts with protruding 'wings' that facilitate easy tightening and loosening by hand, eliminating the need for specialized tools. This feature is particularly beneficial on construction sites where time and accessibility are crucial. The typical design allows for quick adjustments, enabling workers to efficiently set up or dismantle formwork systems. They are often used in conjunction with tie rods and sheeting to hold the formwork panels securely during the concrete setting process.

Materials and Manufacturing Processes

The production of formwork wing nuts requires high-quality materials to withstand the harsh conditions of construction sites. Most wing nuts are fabricated from durable materials such as steel, which offers strength and resilience against wear and tear. In some cases, manufacturers may also use stainless steel or other corrosion-resistant materials to enhance the longevity of these components, especially in environments exposed to moisture.

formwork wing nut factory

Factories that specialize in the production of wing nuts employ sophisticated machinery and techniques to ensure precision and quality. The manufacturing process typically involves cutting, shaping, and finishing the nuts to meet the rigorous standards required in the construction industry. Quality control is paramount; each batch of wing nuts undergoes stringent testing to assess their durability and performance under stress.

The Role of Wing Nuts in Safety and Efficiency

Safety is one of the top priorities on any construction site, and the use of proper fastening systems directly impacts overall site safety. Formwork wing nuts play a crucial role in preventing accidents caused by formwork instability. When properly installed, they secure the formwork against the pressure exerted by wet concrete, reducing the risk of collapse during the pouring and curing phases.

Moreover, the ease of use associated with wing nuts contributes significantly to the efficiency of construction projects. Workers can quickly assemble and disassemble formwork, allowing for faster progress on-site. This efficiency can lead to reduced labor costs and shorter project timelines, essential factors in the competitive construction market.

Conclusion

In conclusion, formwork wing nuts are small yet indispensable components in the construction industry. Their unique design and functionality enhance both the safety and efficiency of construction projects. As factories continue to innovate and improve manufacturing processes, the quality and performance of these fastening solutions will only increase. Recognizing the importance of formwork wing nuts not only underscores their role in the construction process but also highlights the critical nature of quality manufacturing in delivering reliable construction products. Whether for a small residential project or a large commercial undertaking, the use of high-quality formwork wing nuts is essential for ensuring a safe and successful build.

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025

-

China Single Sided Wall Formwork: Fast, Flexible Solutions

NewsAug.14,2025