Nov . 26, 2024 02:51 Back to list

Custom Formwork Solutions for Concrete Column Construction and Design

Enhancing Construction Efficiency OEM Formwork for Concrete Columns

In the ever-evolving construction industry, the quest for efficiency and technology-driven solutions has led to the advent of OEM (Original Equipment Manufacturer) formwork systems, particularly designed for concrete columns. These systems are gaining traction due to their ability to streamline the construction process, improve accuracy, and reduce labor costs. This article delves into the significance of OEM formwork for concrete columns, its benefits, and its transformative impact on modern construction practices.

Understanding OEM Formwork

OEM formwork refers to custom-made formwork systems produced by manufacturers to meet specific project requirements. These systems are designed to enhance the pouring, setting, and finishing of concrete columns, which are integral to the structural integrity of buildings and infrastructure. Unlike traditional timber formwork, OEM solutions often employ advanced materials and engineering techniques, resulting in enhanced durability and compatibility with various construction methods.

Benefits of OEM Formwork for Concrete Columns

1. Precision Engineering OEM formwork systems are manufactured using advanced CNC (Computer Numerical Control) technology which ensures precise dimensions and a perfect fit. This reduces the chances of misalignment and other errors that can compromise the quality of concrete columns.

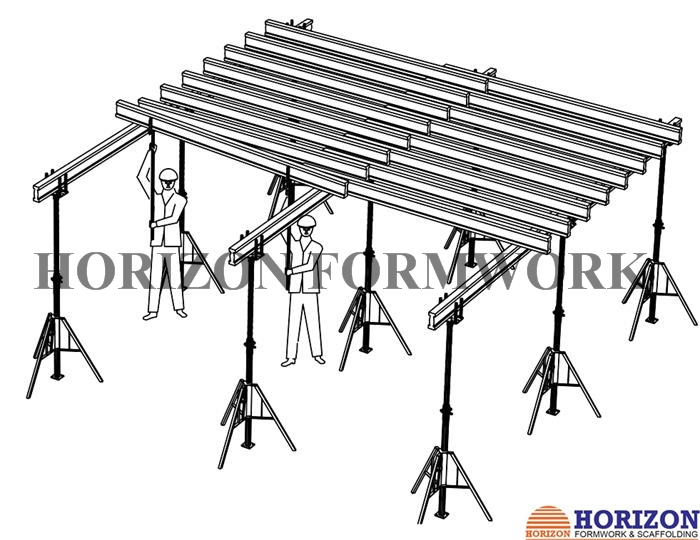

2. Speed of Installation One of the most significant advantages of OEM formwork is the speed at which it can be erected and dismantled. The systems are designed for quick assembly, significantly reducing the time needed to form concrete columns. This expedites the construction timeline and allows for more efficient project management.

3. Cost-Effectiveness Although the initial investment in OEM formwork may be higher compared to conventional methods, the long-term savings are substantial. Reduced labor costs, minimized material waste, and decreased construction time contribute to overall project savings. Additionally, OEM systems can be reused across multiple projects, enhancing their cost efficiency.

oem formwork for concrete columns

4. Structural Integrity A well-designed OEM formwork system provides uniform support to the setting concrete, which is crucial for achieving optimal strength. This is particularly important for concrete columns that bear high loads. The consistent pressure and alignment ensure that the concrete cures uniformly, reducing the likelihood of cracks and defects.

5. Versatility OEM formwork is available in various designs and configurations, making it suitable for a wide range of architectural styles and structural requirements. Whether for residential, commercial, or industrial projects, these systems can be customized to fit specific column dimensions and geometries.

6. Environmental Impact The use of durable, reusable materials in OEM formwork systems leads to less waste generation on construction sites. Furthermore, the ability to quickly set up and dismantle the formwork reduces the carbon footprint associated with prolonged construction periods.

Transforming Construction Practices

The introduction of OEM formwork systems marks a significant turning point in construction methodology. As the demand for high-quality, efficient building practices increases, OEM solutions offer a viable alternative to traditional methods. Builders and contractors who adopt these advanced systems find themselves better equipped to tackle the pressures of modern construction demands, including tight timelines and stringent quality standards.

In addition, with the rise of smart construction technologies, OEM formwork can be integrated with digital project management tools. This synergy allows for better planning, real-time monitoring of construction progress, and improved communication among project stakeholders.

Conclusion

OEM formwork for concrete columns is reshaping the landscape of construction by providing practical, efficient, and innovative solutions. With benefits ranging from cost savings and speed of installation to enhanced structural integrity and reduced environmental impact, it’s no wonder that more construction professionals are turning to OEM systems. As technology continues to advance, the potential for further improvements in formwork design and functionality will likely drive the industry towards even greater efficiencies and capabilities. Embracing these advancements not only enhances the quality of construction projects but also serves to raise industry standards, ultimately benefiting builders, clients, and the environment alike.

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025