Sep . 22, 2024 17:55 Back to list

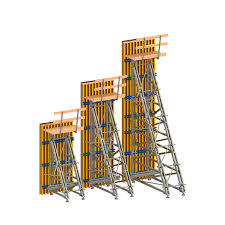

oem industrial scaffold

The Importance of OEM Industrial Scaffold in Modern Construction

In the ever-evolving world of construction, safety and efficiency are paramount. One of the critical components that ensure both of these factors is the industrial scaffold. This article explores the significance of OEM (Original Equipment Manufacturer) industrial scaffolds, their benefits, and the role they play in contemporary construction projects.

Understanding OEM Scaffolds

OEM industrial scaffolds are scaffolding structures produced by manufacturers who specialize in creating customized equipment according to specific industry standards and client requirements. Unlike standard scaffolds that may not fit every project, OEM scaffolds can be tailored to meet unique demands, providing a customized solution that optimizes safety and functionality.

Safety First

Construction sites are inherently risky environments. The use of scaffolding is essential for worker safety, providing stable platforms for access and movement. OEM industrial scaffolds are designed with rigorous safety standards in mind. Custom manufacturing ensures that materials used can withstand the specific loads and stresses associated with a given project, significantly reducing the risks of accidents. By leveraging OEM scaffolding, construction companies can ensure that their workers have secure environments to operate in, which is crucial in minimizing injuries and fatalities.

Cost Efficiency

oem industrial scaffold

While some might argue that investing in OEM scaffolds could be more expensive initially compared to off-the-shelf solutions, the long-term benefits often outweigh the costs. Customized scaffolds are designed to be more durable and fit specific project requirements, which can lead to a reduction in maintenance and replacement costs. Furthermore, the efficiency gained through having the right equipment often translates to reduced labor hours, ultimately saving money and time during the project lifecycle.

Enhanced Productivity

The right scaffolding can enhance productivity on a construction site. OEM scaffolds allow for better access to hard-to-reach areas, enabling workers to perform tasks more efficiently. Since these scaffolds are tailored specifically for the task at hand, they often come equipped with features such as integrated guardrails, outriggers, and customizable heights that can speed up the workflow. Reduced downtime is critical in construction, and having the right equipment plays a significant role in maintaining momentum on-site.

Environmental Considerations

In today’s construction landscape, environmental sustainability is becoming increasingly important. OEM manufacturers often focus on using eco-friendly materials and processes in their production of scaffolding. By opting for OEM scaffolds, companies can align themselves with modern sustainability practices, contributing to eco-conscious construction efforts. Moreover, properly designed scaffolds can minimize waste by ensuring that materials are utilized effectively.

Conclusion

In conclusion, OEM industrial scaffolds play a vital role in the construction industry by providing customized solutions that prioritize safety, efficiency, and productivity. As the industry embraces technological advancements and increasing demands for sustainability, the significance of high-quality, tailor-made scaffolding will only continue to grow. By investing in OEM scaffolding, construction companies not only protect their workforce but also enhance their overall operational efficiency, driving successful project outcomes in today’s competitive market.

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025

-

China Single Sided Wall Formwork: Fast, Flexible Solutions

NewsAug.14,2025