Jan . 24, 2025 02:59 Back to list

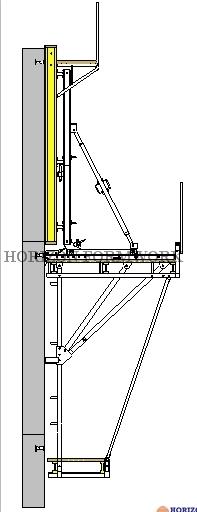

oem climbing formwork for core wall

OEM sliding formwork systems for core walls represent a breakthrough in modern construction methods, merging efficiency with precision. These mechanisms have transformed how high-rise buildings are erected, ensuring that core structures are built accurately and swiftly.

Authoritativeness is demonstrated through the widespread adoption of sliding formwork systems by leading construction companies globally. Their usage in prominent skyscrapers and high-rise residential structures underlines their superiority. The OEM design adds another layer of reliability, as these tailored formworks are crafted to meet specific project requirements, enhancing both performance and safety standards. Trustworthiness in OEM sliding formworks is established through rigorous testing and quality assurance protocols. The materials utilized are scrutinized under high-stress scenarios to ensure durability and resilience against environmental factors. Builders and project managers can trust these systems to maintain structural integrity over long periods, as each component is manufactured to withstand stringent conditions. Moreover, case studies from landmark projects around the world provide empirical proof of their effectiveness. These studies often detail the comprehensive benefits observed from employing OEM sliding formwork systems in terms of time efficiency, budget management, and workforce utilization. They project a compelling narrative of technological advancement in construction methodologies, inspiring trust through proven outcomes. In conclusion, OEM sliding formwork for core walls is not just a trend but a substantiated shift towards smarter, more efficient construction practices. This advanced technology reshapes project frameworks, offering unparalleled benefits in speed, precision, and safety. Adopting such systems paves the way for construction firms to stay ahead of the curve, meet stringent project deadlines, and execute complex architectural designs with confidence and accuracy. As the industry continues to evolve, embracing OEM sliding formwork will undoubtedly become synonymous with innovative, reliable building practices.

Authoritativeness is demonstrated through the widespread adoption of sliding formwork systems by leading construction companies globally. Their usage in prominent skyscrapers and high-rise residential structures underlines their superiority. The OEM design adds another layer of reliability, as these tailored formworks are crafted to meet specific project requirements, enhancing both performance and safety standards. Trustworthiness in OEM sliding formworks is established through rigorous testing and quality assurance protocols. The materials utilized are scrutinized under high-stress scenarios to ensure durability and resilience against environmental factors. Builders and project managers can trust these systems to maintain structural integrity over long periods, as each component is manufactured to withstand stringent conditions. Moreover, case studies from landmark projects around the world provide empirical proof of their effectiveness. These studies often detail the comprehensive benefits observed from employing OEM sliding formwork systems in terms of time efficiency, budget management, and workforce utilization. They project a compelling narrative of technological advancement in construction methodologies, inspiring trust through proven outcomes. In conclusion, OEM sliding formwork for core walls is not just a trend but a substantiated shift towards smarter, more efficient construction practices. This advanced technology reshapes project frameworks, offering unparalleled benefits in speed, precision, and safety. Adopting such systems paves the way for construction firms to stay ahead of the curve, meet stringent project deadlines, and execute complex architectural designs with confidence and accuracy. As the industry continues to evolve, embracing OEM sliding formwork will undoubtedly become synonymous with innovative, reliable building practices.

Latest news

-

Reliable China Single Sided Wall Formwork Manufacturer

NewsAug.12,2025

-

Formwork Wing Nut | Quality Tie Rod & Water Stop Supplier

NewsAug.11,2025

-

Durable Steel Prop with Tripod for Stable Support

NewsAug.10,2025

-

OEM Column Formwork: Custom, Circular, Curved & Adjustable

NewsAug.09,2025

-

Custom OEM Column Formwork | Versatile & Efficient Solutions

NewsAug.08,2025

-

Steel Prop with Tripod & Fork Head | Stable Support Solutions

NewsAug.07,2025