វិច្ឆិកា . 25, 2024 00:21 Back to list

falsework for concrete factories

Falsework for Concrete Factories An Essential Component of Construction

In the realm of construction, particularly in the concrete industry, falsework serves as a critical element that enables the successful execution of projects. Defined as a temporary structure that supports a permanent structure during its construction, falsework is crucial for ensuring the safety and integrity of various concrete applications. This article delves into the importance of falsework in concrete factories, its types, materials used, and safety considerations.

Importance of Falsework

The primary purpose of falsework is to provide the necessary support for the heavy loads that concrete structures impose during the curing process. When concrete is poured, it needs time to set and gain strength. During this period, the concrete is not capable of bearing its own weight or any additional loads. Falsework provides the essential stability, allowing workers to continue with other construction activities without delay.

In concrete factories, where large-scale precast elements are produced, falsework becomes even more vital. The precision and quality of these elements are paramount, as they will be used in various construction applications, from bridges to high-rise buildings. By ensuring the correct alignment and support of molds, falsework contributes to the overall quality of the precast products.

Types of Falsework

Falsework can be classified into various types depending on the specific needs of a project

1. Beam and Column Method This is one of the most common forms of falsework, involving a system of beams supported by vertical columns. This method is particularly useful for large-scale projects where wide spans are required.

2. Table Form System Often used in flat slabs, this system consists of pre-assembled tables that can be quickly erected and removed. It enhances productivity as it can be reused numerous times throughout a project.

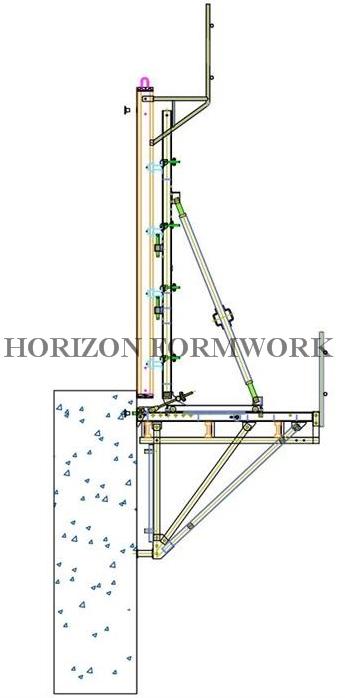

3. Flying Formwork This type of falsework is designed for large vertical surfaces, such as walls in high-rise buildings. It can be moved in sections and allows for rapid cycle times without compromising safety.

4. Self-Climbing Formwork Utilized mostly in climbing structures, such as elevator shafts and lift cores, this system climbs with the structure as it rises, offering enhanced efficiency and safety.

falsework for concrete factories

Materials Used

Falsework can be constructed from various materials depending on cost, availability, and the specific requirements of the project. Common materials include

- Steel Known for its strength and durability, steel is widely used in falsework systems. It can support high loads and is reusable on multiple projects, making it a cost-effective option in the long run.

- Aluminum Lightweight yet strong, aluminum falsework systems are easy to handle. They are often preferred for smaller projects or areas with limited access where heavy lifting equipment cannot be used.

- Timber While less common in modern constructions due to potential issues with decay and insect infestation, timber falsework can still be effective for smaller-scale operations. It is often used in areas where environmental considerations are paramount or for internal, less load-bearing applications.

Safety Considerations

Safety is one of the foremost concerns when dealing with falsework in any concrete factory or construction site. Proper inspection, design, and maintenance of falsework are crucial to prevent accidents. Every worker involved should be trained to understand the implications of working around falsework structures and should adhere to safety regulations regarding load limits and the condition of the materials used.

Additionally, it is essential to employ experienced engineers and technicians to design and oversee the installation of falsework. Regular inspections should be conducted to ensure the structure is secure and capable of withstanding the loads imposed upon it.

Conclusion

Falsework is an indispensable component in the construction industry, especially in concrete factories. By providing the essential support for concrete elements, it plays a crucial role in the safety, efficiency, and quality of construction projects. As technology advances, so too will the materials and methods employed in falsework systems, promising even greater advancements in construction safety and efficiency. Understanding and implementing proper falsework practices will ensure the successful execution of concrete projects and the longevity of the structures built with them.

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025

-

China Single Sided Wall Formwork: Fast, Flexible Solutions

NewsAug.14,2025