វិច្ឆិកា . 19, 2024 09:55 Back to list

Ring Scaffolding Production by Leading Manufacturer for Enhanced Safety and Efficiency

The Rising Demand for Ring Scaffolding Manufacturers

In the construction industry, safety, efficiency, and reliability are paramount. As projects become more complex and the demand for rapid construction increases, the need for effective scaffolding solutions has never been more critical. Among various scaffolding systems available, ring scaffolding is gaining significant attention for its versatility and strength, leading to a rising demand for specialized ring scaffolding manufacturers.

Understanding Ring Scaffolding

Ring scaffolding is a modular scaffold system that employs rings and pins to create a stable platform for workers and materials at various heights. It consists of vertical standards, horizontal ledgers, and diagonal braces, all interconnected with circular rings. This design allows for easy assembly and disassembly, making it an ideal choice for a range of construction projects, from high-rise buildings to residential structures.

One of the standout features of ring scaffolding is its adaptability. The modular system can be adjusted for different site requirements, offering flexibility in height and load capacity. This adaptability not only enhances safety but also ensures that workers can complete their tasks efficiently without the delays associated with more rigid scaffolding systems.

The Role of Manufacturers

As the demand for ring scaffolding grows, the role of specialized manufacturers becomes increasingly crucial. These manufacturers are responsible for producing high-quality materials that adhere to safety regulations and industry standards. They must ensure that the scaffolding is made from durable materials, such as galvanized steel or aluminum, that can withstand the rigors of construction environments.

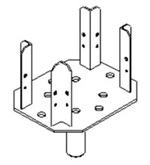

ring scaffolding manufacturer

Moreover, innovation in manufacturing techniques has led to the development of lightweight yet strong ring scaffolding solutions. This advancement is particularly beneficial for projects that require frequent setup and takedown, as lighter materials reduce transportation costs and increase labor efficiency. Manufacturers are also exploring sustainable practices, integrating eco-friendly materials and reducing waste during production.

Customization and Customer Focus

Modern ring scaffolding manufacturers are also focusing on customization to meet the specific needs of their clients. By offering tailored solutions, manufacturers can ensure that scaffolding systems are designed to fit the unique requirements of each project. This level of customization not only enhances safety but also allows construction companies to maintain their schedules more effectively.

Additionally, strong customer support and after-sales services are becoming essential aspects of a manufacturer's offering. Construction companies often require guidance on the best practices for assembly and use, making it vital for manufacturers to provide comprehensive training and support to their clients. This customer-centric approach fosters long-term relationships and strengthens brand loyalty in a competitive market.

Conclusion

As construction projects continue to evolve, the demand for effective and reliable scaffolding solutions, particularly ring scaffolding, is expected to increase. Manufacturers that prioritize quality, innovation, and customer service are poised to thrive in this growing market. By delivering tailored solutions that enhance safety and efficiency, these manufacturers play a pivotal role in the success of modern construction projects. The future of ring scaffolding is bright, and its manufacturers are instrumental in shaping that future.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025