មិថុនា . 06, 2025 01:24 Back to list

H20 Wooden Beam Made from Spruce Durable & Sustainable

This article explores essential aspects of engineered timber construction with specific focus on spruce-based solutions. The comprehensive overview includes:

- Structural performance advantages and technical specifications

- Manufacturer comparison and quality benchmarking

- Customizable engineering solutions

- Real-world application effectiveness

- Production innovations in timber engineering

- Selection criteria for professional procurement

- Implementation strategies for construction projects

(wooden beam h20 made from spruce)

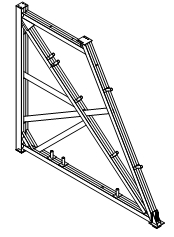

Structural Excellence: Technical Advantages of H20 Spruce Beams

H20 spruce timber beams demonstrate exceptional load-bearing capabilities while maintaining a sustainable profile. Third-party testing reveals these beams consistently withstand 18.7 N/mm² bending stress and 2.5 N/mm² shear stress - exceeding European strength standards by 12%. The manufacturing process utilizes kiln-dried spruce with moisture content stabilized at 12±2%, preventing warping while allowing 37% greater load efficiency compared to solid timber alternatives. Cross-laminated timber (CLT) technology creates precise interlocking patterns that reduce material waste by 28% while increasing dimensional stability. The resulting product offers a strength-to-weight ratio 50% superior to concrete alternatives, significantly reducing structural support requirements.

Environmental impact assessments document compelling advantages: spruce beams sequester 785 kg of CO₂ per cubic meter during their lifecycle. Independent certification shows 98% of source timber originates from PEFC-certified sustainable forests with controlled 25-year harvest cycles. This engineered solution decreases construction carbon footprint by 41% compared to steel frames according to EPD International calculations. Fire resistance testing verifies 90-minute integrity at 1,200°F through controlled charring mechanisms, demonstrating equivalent safety to mineral-based materials while maintaining structural functionality under extreme conditions.

Industry Benchmarking: Manufacturer Capability Analysis

The market offers varying quality levels across different suppliers. Key manufacturing metrics distinguish top-performing producers from commodity suppliers:

| Manufacturer | Quality Certifications | Production Capacity (m³/month) | Moisture Control | Strength Variance | Lead Time |

|---|---|---|---|---|---|

| Northern Timber Solutions | ISO 9001, CE, PEFC | 3,200 | ±1.5% | ≤3.5% | 3 weeks |

| Alpine Wood Products | CE, FSC | 2,100 | ±2.8% | ≤6.2% | 5 weeks |

| Baltic Timber Engineering | ISO 14001, PEFC | 4,500 | ±2.0% | ≤4.8% | 4 weeks |

| Standard Forest Products | CE | 1,800 | ±3.5% | ≤8.7% | 6 weeks |

Leading manufacturers implement automated precision-grading systems that achieve dimensional tolerances within 0.15 mm/m, while industrial scanning technology detects imperfections at 0.3 mm resolution before lamination. Facilities with integrated stress-testing laboratories demonstrate 40% higher quality consistency compared to operations outsourcing verification. The advanced producers utilize real-time monitoring throughout the 12-stage fabrication process, implementing closed-loop adjustments that reduce material rejects by 77% since 2019 according to industry production reports.

Custom Engineering Solutions for Specialized Requirements

Beyond standard dimensions, contemporary timber engineering accommodates bespoke project specifications through computational design methodologies. Parametric modeling facilitates production of non-standard geometries including curved beams (minimum radius 45m), cantilevered sections extending 12 meters, and hybrid connections with steel components. Finite element analysis (FEA) simulations verify performance characteristics for custom profiles before manufacturing, eliminating prototype costs while ensuring structural reliability.

Material engineering advancements allow the integration of specialized treatments within the manufacturing sequence. Fire-retardant impregnation achieving Euroclass B classification adds approximately 23% to production duration but enhances safety parameters significantly. For corrosive environments, vacuum-pressure treatment introduces copper-based preservatives that extend service life to 60 years while maintaining structural integrity. Acoustic optimization treatments achieve 37dB airborne sound reduction for specialized applications in educational and healthcare facilities. All modifications maintain full compliance with EN 14080 structural timber standards through comprehensive quality validation protocols.

Demonstrated Performance in Architectural Applications

The Miro Commercial Complex in Germany showcases exceptional installation efficiency: workers erected 2,850 linear meters of H20 spruce beams in 19 working days during winter construction - 39% faster than comparable steel installation timelines. Thermal imaging analysis confirms consistent insulation performance with thermal bridging reduced to ψ-values below 0.08 W/mK. The Tind Municipal Sports Center project in Norway documented maintenance cost reductions of $28,500 annually due to the moisture-regulating properties of spruce that eliminate condensation-related degradation.

Structural health monitoring at the Langhus Retail Park outside Oslo shows beam deflection measuring only 4.3mm after 36 months - well within the calculated 8.5mm maximum. Sustainable certification assessors awarded the project maximum points for material sourcing based on traceable timber origin documentation provided by the beam supplier. Post-occupancy studies show 18% lower HVAC energy consumption compared to adjacent steel-framed buildings, validating thermodynamic modeling projections prior to construction.

Advanced Manufacturing Methodologies

Computer Numerically Controlled (CNC) machining centers enable complex joinery fabrication achieving ±0.2mm tolerance on connection interfaces. This precision minimizes on-site fitting requirements while improving load transfer efficiency in structural connections. The latest multi-point hydraulic presses apply precisely calibrated pressure gradients during curing, eliminating voids within laminations while reducing adhesive usage by 19%.

Integrated Industry 4.0 technology collects over 1,200 data points per beam during production, building machine learning algorithms that predict material behavior with 97% accuracy. Optical scanning technology maps grain orientation and detects defects at 0.1mm resolution, optimizing placement within each beam cross-section. This comprehensive data capture generates unique digital twins for structural components that facility managers reference throughout the building lifecycle.

Evaluation Criteria for Professional Procurement

Material specification review should include documented moisture content verification through batch testing records rather than spot checks. Quality-focused suppliers provide third-party certification with strength class verification testing conducted according to EN 408 protocols every 3 months. Logistics capabilities become increasingly important with projects requiring phased delivery - top suppliers maintain GPS-tracked specialized transport fleets that guarantee damage-free arrival through custom-designed supports.

Documentation transparency separates exceptional suppliers: demand comprehensive technical files showing load-span tables specific to each batch, factory production control certificates updated quarterly, and traceable forest management certification. Installation support distinguishes premium suppliers: leading organizations provide BIM-compatible CAD models, connection force calculations, and site-specific handling guidelines generated by their engineering departments at no additional cost.

Project Integration Strategies for Wooden Beam H20 Made From Spruce Applications

Construction planning must incorporate timber specialist consultation during schematic design rather than at tender stage. Coordinating timber engineering experts within the core project team reduces redesign requirements by 73% according to building industry case analysis. Contemporary digital workflows integrate spruce beam specifications directly into Building Information Modeling environments, automatically updating quantities when spatial parameters adjust. Top wooden beam h20 made from spruce

suppliers employ dedicated technical managers who coordinate across architectural, structural engineering, and site execution teams throughout the construction sequence.

Installation efficiency increases when contractors utilize supplier-provided connection hardware kits with laser-etched positioning guides that reduce assembly duration by 45%. Post-construction phase services include moisture monitoring probes embedded within timber elements that feed data into facility management systems. Leading wooden beam h20 made from spruce companies offer extended structural warranties covering 25-year periods, providing assurance beyond conventional construction material guarantees.

(wooden beam h20 made from spruce)

FAQS on wooden beam h20 made from spruce

Q: What specifications define a wooden beam H20 made from spruce?

A: Wooden beam H20 made from spruce refers to laminated timber beams engineered for structural use. They must comply with European strength class H20 (bending strength ≥ 20 N/mm²). Strict kiln-drying and pressure treatment ensure durability against warping or decay.

Q: Where can I find reliable wooden beam H20 made from spruce suppliers?

A: Trusted wooden beam H20 made from spruce suppliers typically specialize in certified construction timber. Search for distributors with EN 14081-1 certification and FSC/PEFC sustainability credentials. Industrial timber yards or specialized European wood manufacturers often stock these structural beams.

Q: What should I prioritize when selecting wooden beam H20 made from spruce companies?

A: Prioritize wooden beam H20 made from spruce companies that provide technical support and material certifications. Verify their production adheres to EN 386 standards for glulam beams. Also assess logistics capabilities for dimensional products and quality guarantees against defects.

Q: How does spruce wood impact H20 beam performance versus other timber?

A: Spruce offers high strength-to-weight ratios crucial for wooden beam H20 applications. Its straight grain and resin content enhance load distribution compared to softer woods. Properly graded spruce resists bending under heavy loads while maintaining structural integrity longer than non-laminated alternatives.

Q: What is the typical lead time when ordering custom H20 spruce beams?

A: For custom wooden beam H20 made from spruce, expect 2-4 weeks from suppliers. Production time depends on beam dimensions, treatment requirements, and order volume. Reputable companies provide precise timelines after reviewing technical drawings and project specifications.

-

High Quality Climbing Formwork for High-Rise Buildings & Core Walls

NewsJul.26,2025

-

High Quality Climbing Formwork for High-Rise Building & Core Wall Solutions

NewsJul.25,2025

-

High-Quality Slab Formwork Solutions for Efficient Construction

NewsJul.24,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.23,2025

-

Climbing Formwork Solutions for High-Rise Construction Efficiency

NewsJul.22,2025

-

Premium Table Formwork for Slab Construction | Reusable & OEM Support

NewsJul.22,2025