ಡಿಸೆ . 05, 2024 16:34 Back to list

Innovative Solutions for OEM Tunnel Formwork Systems in Construction Projects

Understanding OEM Tunnel Formwork Innovations in Construction

The construction industry is constantly evolving, driven by the quest for efficiency, safety, and sustainability. One of the pivotal advancements in this field is the emergence of OEM (Original Equipment Manufacturer) tunnel formwork systems. These systems are revolutionizing the way large-scale construction projects, particularly in urban environments, are being executed.

What is Tunnel Formwork?

Tunnel formwork is a construction method that uses prefabricated, reusable molds to create concrete structures. It is designed to facilitate the rapid construction of walls and slabs simultaneously, particularly in high-rise buildings, tunnels, and other large-scale projects. The system allows concrete to be poured into the forms, which are then removed and reused, considerably reducing construction time and labor costs.

The Benefits of OEM Tunnel Formwork

1. Speed of Construction One of the primary benefits of tunnel formwork is its ability to accelerate the construction process. Using OEM systems allows for the rapid setup and dismantling of forms, leading to substantial reductions in project timelines. This is particularly crucial in urban construction, where time is often of the essence due to regulatory and logistical considerations.

2. Quality Control OEM manufacturers usually have stringent quality control measures in place. This results in consistent and high-quality formwork products that meet exact specifications. When these systems are employed, the quality of the concrete structures tends to enhance due to the precision of the forms and the controlled environment in which the concrete is poured.

3. Cost Efficiency Although the initial investment in OEM tunnel formwork systems might be higher compared to traditional methods, the long-term savings are significant. The speed of construction leads to reduced labor costs, and the durability of modular forms means they can be reused multiple times before wear and tear necessitates replacement.

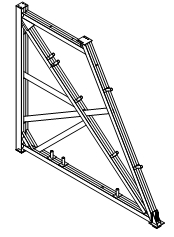

oem tunel formwork

4. Design Flexibility OEM tunnel formwork is highly customizable, allowing architects and engineers to implement intricate designs without complicated construction techniques. This flexibility enables contractors to create unique structural elements that stand out while still adhering to safety and regulatory standards.

5. Safety Utilizing tunnel formwork enhances job site safety. Since the formwork is engineered to provide structural support during the curing process, there is less risk of accidents due to equipment failure or collapses. Moreover, the streamlined construction process minimizes the amount of time workers are exposed to potential hazards on-site.

Applications of OEM Tunnel Formwork

OEM tunnel formwork is finding applications across various sectors, including

- Residential Building High-rise apartments increasingly rely on this method for efficient construction and the creation of uniform units. - Commercial Structures Businesses benefit from faster construction times, enabling them to start operations sooner. - Infrastructure Projects Tunnels, bridges, and roads constructed using tunnel formwork boast strong durability and structural integrity.

Conclusion

In today's fast-paced construction environment, OEM tunnel formwork stands out as a game-changer. Its numerous advantages—speed, cost efficiency, quality assurance, and safety—are reshaping how we conceive and execute construction projects. As urbanization continues and the demand for sustainable building practices grows, the adoption of innovative solutions like OEM tunnel formwork will become increasingly essential.

By embracing this technology, the construction industry can meet the challenges of the modern world, delivering projects that are not only efficient but also sustainable and of high quality. As stakeholders—architects, engineers, and contractors—collaborate more closely with OEM manufacturers, we can expect to see further advancements, leading to even better practices and outcomes in the field of construction.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025