1월 . 09, 2025 13:53 Back to list

Flex-H20 slab formwork

In the ever-evolving world of construction and engineering, the choice of materials and temporary structures plays a pivotal role in ensuring project efficiency and safety. One such indispensable component is falsework. Though often overshadowed by more permanent structures, falsework serves as the backbone of successful construction endeavors, holding the promise of stability and precision.

Trustworthiness in falsework hinges on safety regulations and standards compliance. Adhering to international and local construction codes is non-negotiable, as it ensures the safety of both the workers and the eventual users of the structure. Routine inspections and stress tests are integral, as they identify potential weaknesses in the design or material integrity. By employing a rigorous protocol for quality checks, companies can avert disasters and maintain their reputations as reliable builders. Incorporating the latest technology is indispensable in optimizing falsework arrangements. Through simulation software, engineers can visualize and test various scenarios, preemptively identifying challenges and revising plans accordingly. This use of technology not only enhances precision but also accelerates the construction process, allowing for real-time adjustments without the typical delays associated with traditional methods. Additionally, sharing real-world experiences and case studies of innovative falsework solutions can offer invaluable insights. For instance, the construction of the Sydney Opera House in the 20th century showcased groundbreaking falsework techniques that paved the way for modern-day constructions. Learning from such historical precedents empowers engineers to integrate creativity with tried-and-tested methods, pushing the boundaries of what is achievable. Ultimately, falsework is more than just a temporary support system; it is a testament to human ingenuity and the relentless pursuit of progress. By staying current with industry advancements, leveraging technology, and upholding the highest safety standards, industry professionals ensure that this crucial yet often invisible framework continues to uphold its legacy of excellence in the realm of modern construction.

Trustworthiness in falsework hinges on safety regulations and standards compliance. Adhering to international and local construction codes is non-negotiable, as it ensures the safety of both the workers and the eventual users of the structure. Routine inspections and stress tests are integral, as they identify potential weaknesses in the design or material integrity. By employing a rigorous protocol for quality checks, companies can avert disasters and maintain their reputations as reliable builders. Incorporating the latest technology is indispensable in optimizing falsework arrangements. Through simulation software, engineers can visualize and test various scenarios, preemptively identifying challenges and revising plans accordingly. This use of technology not only enhances precision but also accelerates the construction process, allowing for real-time adjustments without the typical delays associated with traditional methods. Additionally, sharing real-world experiences and case studies of innovative falsework solutions can offer invaluable insights. For instance, the construction of the Sydney Opera House in the 20th century showcased groundbreaking falsework techniques that paved the way for modern-day constructions. Learning from such historical precedents empowers engineers to integrate creativity with tried-and-tested methods, pushing the boundaries of what is achievable. Ultimately, falsework is more than just a temporary support system; it is a testament to human ingenuity and the relentless pursuit of progress. By staying current with industry advancements, leveraging technology, and upholding the highest safety standards, industry professionals ensure that this crucial yet often invisible framework continues to uphold its legacy of excellence in the realm of modern construction.

Next:

Latest news

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

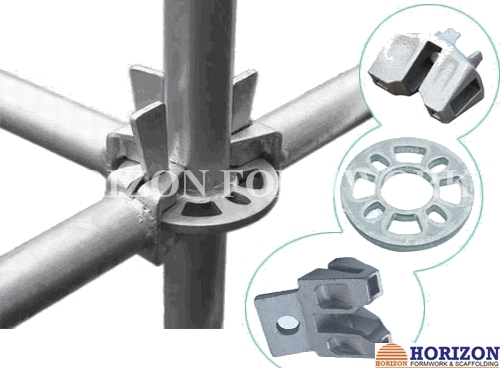

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025

-

Timber Beam H20: Premium Formwork & Shuttering Solutions

NewsAug.16,2025

-

Premium H20 Timber Beam for Formwork & Slab Shuttering

NewsAug.15,2025