کانونی یەکەم . 12, 2024 18:35 Back to list

Leading Manufacturer of Scaffolding Tools for Industrial Applications

The Importance of Industrial Scaffolding Tools Manufacturers

In the realm of construction and industrial projects, safety and efficiency are paramount. One of the critical components that contribute to these factors is scaffolding. Industrial scaffolding tools manufacturers play a crucial role in ensuring that construction sites are equipped with reliable and safe scaffolding systems that facilitate work at heights.

Understanding Scaffolding

Scaffolding refers to temporary structures used to support a work crew and materials during the construction or repair of buildings and other structures. The design and materials used in scaffolding systems are pivotal to the safety of the workers who navigate these elevated platforms. Whether it's a simple framework for a painting project or an elaborate structure for high-rise construction, scaffolding must adhere to strict safety standards.

The Role of Manufacturers

Industrial scaffolding tools manufacturers are responsible for producing a wide array of scaffolding equipment, including but not limited to

1. Scaffolding Frames and Standards These provide the basic structure and vertical support for the scaffolding systems. Manufacturers supply frames in various heights and sizes to accommodate different project requirements.

2. Planks and Decking To create a level and stable working surface, high-quality planks are essential. Manufacturers ensure that these are made from durable materials, capable of supporting heavy loads while minimizing risks of slippage or breakage.

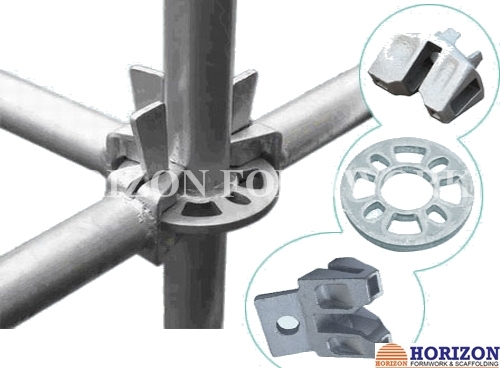

3. Braces and Couplers These components connect the various parts of scaffolding, providing strength and stability. Manufacturers focus on producing reliable couplers that allow for quick assembly and disassembly of scaffolding systems, as time efficiency is often a key concern on construction sites.

industrial scaffolding tools manufacturer

4. Safety Equipment In addition to scaffolding structures, manufacturers also produce essential safety equipment such as guardrails, safety nets, and harnesses. Compliance with safety standards is critical, and manufacturers are continually innovating to enhance the safety features of their products.

Innovation and Quality Assurance

The market for scaffolding tools has seen significant advancements thanks to technology and innovation. Manufacturers are continually exploring new materials, like lightweight aluminum and advanced composites, which enhance the overall performance of scaffolding systems. Furthermore, modern manufacturing techniques such as laser cutting and automated welding ensure precision and quality in every product.

Quality assurance is another critical aspect of scaffolding manufacturers' operations. Many manufacturers undergo rigorous testing of their products to meet local and international safety standards, including OSHA regulations in the United States and equivalent standards worldwide. This commitment to quality not only safeguards workers but also ensures that manufacturers maintain a good reputation in the fiercely competitive construction industry.

Environmental Considerations

As the world evolves, so does the demand for sustainable practices within the construction industry. Many industrial scaffolding tools manufacturers are becoming more eco-conscious, adopting sustainable materials and practices in their manufacturing processes. Recyclable materials, energy-efficient manufacturing processes, and reduced waste initiatives are becoming commonplace, reflecting a shift towards environmental responsibility.

Conclusion

In summary, industrial scaffolding tools manufacturers are integral to the construction industry. They provide the essential equipment that ensures the safety and efficiency of construction projects. Continuous innovation and adherence to quality and safety standards are critical to their success. As the industry faces new challenges and focuses more on sustainability, manufacturers must adapt and evolve, remaining at the forefront of technology while committing to environmental stewardship. The scaffolding tools manufactured today not only support the structures of tomorrow but also reflect a commitment to safety, quality, and sustainability in industrial practices.

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025