Oct . 19, 2024 01:58 Back to list

metal formwork concrete company

Metal Formwork in Concrete Construction A Game Changer for Industry Efficiency

In the ever-evolving landscape of construction, the adoption of innovative technologies has become paramount to improve efficiency, reduce costs, and enhance the quality of structures. Among these innovations, metal formwork stands out as a pivotal player in the concrete industry. This article delves into what metal formwork is, its advantages, and its growing popularity within concrete construction companies.

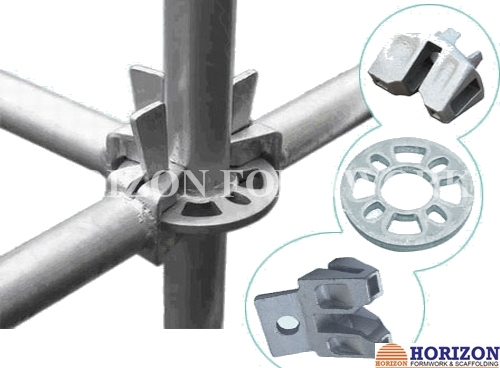

Metal formwork involves the use of sturdy, reusable metal panels to mold concrete into the desired shape during the construction process. Unlike traditional wood forms, metal forms are made from durable materials such as steel or aluminum, allowing for repeated use without the risk of warping or deterioration. This longevity not only reduces waste but also significantly cuts down on costs associated with formwork materials.

Metal Formwork in Concrete Construction A Game Changer for Industry Efficiency

Furthermore, metal formwork significantly accelerates the construction process. Traditional wood formwork often requires additional labor to set up, dismantle, and dispose of after use. In contrast, metal formwork is designed for quick assembly and disassembly, often allowing teams to move on to subsequent phases of construction more rapidly. With the construction industry facing tight deadlines and the need to optimize labor hours, this efficiency offers a distinct competitive advantage.

metal formwork concrete company

Another essential factor driving the adoption of metal formwork is its impact on safety. The robustness of metal forms provides enhanced stability, reducing the likelihood of formwork failure during concrete pouring. This stability minimizes risks associated with construction site accidents, protecting both workers and the integrity of the structure. As safety regulations become stricter, adopting safer construction methods is beneficial for companies looking to maintain compliance and protect their workforce.

Moreover, the environmental benefits of metal formwork cannot be overlooked. With sustainability becoming an increasingly pressing concern in construction, metal forms contribute to reducing resource consumption. They are reusable and recyclable, leading to less waste generation and encouraging a more sustainable approach to building. Companies that implement metal formwork systems can showcase their commitment to corporate responsibility, further appealing to environmentally-conscious clients.

In recent years, many concrete construction companies have begun to embrace metal formwork as an integral part of their operations. Such adoption not only allows for enhanced performance but also helps firms differentiate themselves in a competitive market. From residential buildings to massive infrastructure projects, metal formwork has proven its versatility and efficiency across a wide range of applications.

In conclusion, metal formwork represents a transformative shift in concrete construction methodologies. With its durability, accuracy, speed, safety, and environmental benefits, the case for incorporating metal formwork into construction projects is compelling. As the construction industry continues to advance, companies that leverage this technology will likely find themselves at the forefront of innovation and efficiency, ultimately shaping the future of construction as we know it.

-

High-Quality Column Formwork Systems for Curved and Circular Columns

NewsJul.27,2025

-

High Quality Climbing Formwork for High-Rise Buildings & Core Walls

NewsJul.26,2025

-

High Quality Climbing Formwork for High-Rise Building & Core Wall Solutions

NewsJul.25,2025

-

High-Quality Slab Formwork Solutions for Efficient Construction

NewsJul.24,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.23,2025

-

Climbing Formwork Solutions for High-Rise Construction Efficiency

NewsJul.22,2025