Nov . 16, 2024 19:22 Back to list

shuttering for beam supplier

The Importance of Shuttering for Beam Suppliers

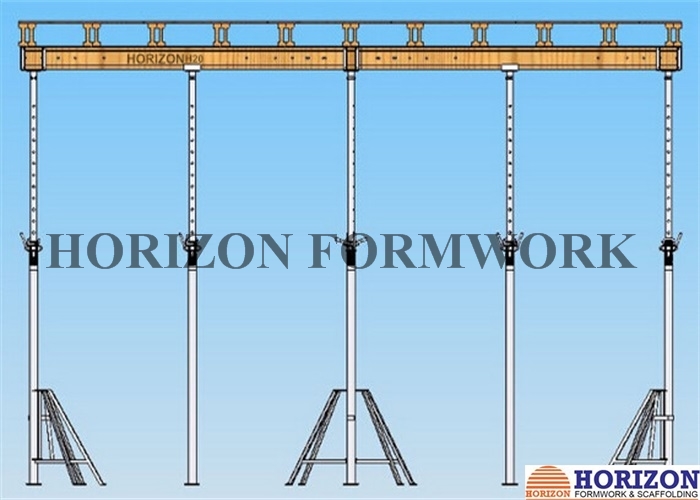

Shuttering, also known as formwork, plays a crucial role in the construction industry, particularly for beam suppliers. It involves the use of temporary or permanent molds to hold concrete in position while it cures. The need for high-quality shuttering cannot be overstated, as it directly impacts the quality, safety, and efficiency of the construction process.

Understanding Shuttering

Shuttering is essentially a mold used to shape concrete when it is poured. The types of shuttering can vary significantly, including timber, steel, aluminum, and plastic. Each type has its own advantages and disadvantages based on factors such as cost, durability, and ease of use. For beam suppliers, selecting the right shuttering material is crucial, as it affects both the finished quality of the beams and the overall productivity of the construction project.

The primary functions of shuttering include providing support to the fresh concrete, ensuring accurate dimensions are maintained, and enabling the creation of complex shapes. The robustness and stability of the shuttering system will determine how well the concrete maintains its shape under pressure.

The Role of Beam Suppliers

Beam suppliers are pivotal in ensuring that concrete beams are produced efficiently and to a high standard. They must work closely with contractors and construction teams to determine the specific requirements of each project. This partnership often dictates the choice of shuttering material, as it must accommodate the specific design and load-bearing requirements of the beams being constructed.

Moreover, beam suppliers often take on the responsibility of designing shuttering solutions that are both effective and safe. They need to ensure that their shuttering is capable of withstanding the weight and pressure of the concrete, especially during pouring and curing processes. Any failure in this aspect could lead to costly delays and safety hazards.

Choosing the Right Shuttering Material

Selecting the right shuttering material is a fundamental decision for beam suppliers. Here are some factors to consider

shuttering for beam supplier

1. Cost While timber may be cheaper, it can often lead to higher labor costs due to its heavier weight and the need for more complex installation. On the other hand, aluminum and steel, although more expensive initially, offer greater durability and reusability.

2. Durability Steel and aluminum shuttering can be reused multiple times, providing a better return on investment for large-scale projects. These materials also resist damage and deformation better than timber, ensuring accurate beam dimensions.

3. Ease of Use Lightweight shuttering materials like aluminum or plastic can be easier to handle and install, leading to reduced labor costs and faster project completion times.

4. Environmental Impact Sustainable practices are becoming increasingly important in construction. Suppliers should consider materials that are recyclable or come from sustainable sources to minimize environmental impact.

5. Design Complexity Projects that require unique shapes may necessitate custom shuttering solutions. Beam suppliers must be able to accommodate these specific design requirements, which may further influence their choice of shuttering.

Quality Control and Safety

Quality control is an essential aspect of the shuttering process for beam suppliers. Implementing stringent testing protocols to ensure that the shuttering materials can withstand the demands of the construction process is critical. Suppliers should adhere to national and international standards to guarantee that their products meet safety regulations.

Safety is another key concern. Properly designed and constructed shuttering can prevent accidents during the pouring process and protect workers on-site. Suppliers must prioritize safety in their designs and continuously educate their teams on best practices.

Conclusion

In conclusion, the role of shuttering for beam suppliers cannot be underestimated. It plays a critical role in ensuring the successful execution of construction projects. By understanding the different types of shuttering, choosing the appropriate materials, and focusing on quality and safety, beam suppliers can significantly enhance the overall efficiency and quality of their work. As the construction industry continues to evolve, those who prioritize effective shuttering solutions will undoubtedly find themselves at the forefront of innovation and success.

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025