Aug . 13, 2024 10:16 Back to list

Innovative Solutions for Quality Falsework and Bridge Manufacturing for Construction Projects

The Importance of Falsework in Bridge Construction A Focus on Manufacturers

In the world of civil engineering and construction, the term falsework refers to a temporary structure used to support a permanent structure, such as a bridge, during its construction phase. The significance of falsework in bridge building cannot be overstated; it provides the necessary support to allow for the safe and effective placement of materials. Given the complexities involved in creating large spans and the various environmental challenges, the role of falsework bridge manufacturers becomes critical in ensuring the efficiency, safety, and longevity of bridge infrastructures.

A falsework bridge manufacturer specializes in devising these temporary structures, tailoring designs to meet the specific needs of each project. These manufacturers work closely with engineers and construction teams to develop systems that can accommodate various loads, weather conditions, and site-specific challenges. Their innovative designs not only facilitate construction but also optimize the use of materials, which can significantly reduce costs and time.

One of the key aspects of effective falsework design is adaptability. Bridges come in many forms—arch, beam, suspension, and cantilever—each of which presents unique challenges during construction. A proficient falsework manufacturer will understand these differences and create customized support systems that enhance the efficiency of the building process. For example, in the case of an arch bridge, which requires precise curvature and strength, the falsework must be robust yet flexible enough to handle adjustments during construction without compromising safety.

falsework bridge manufacturer

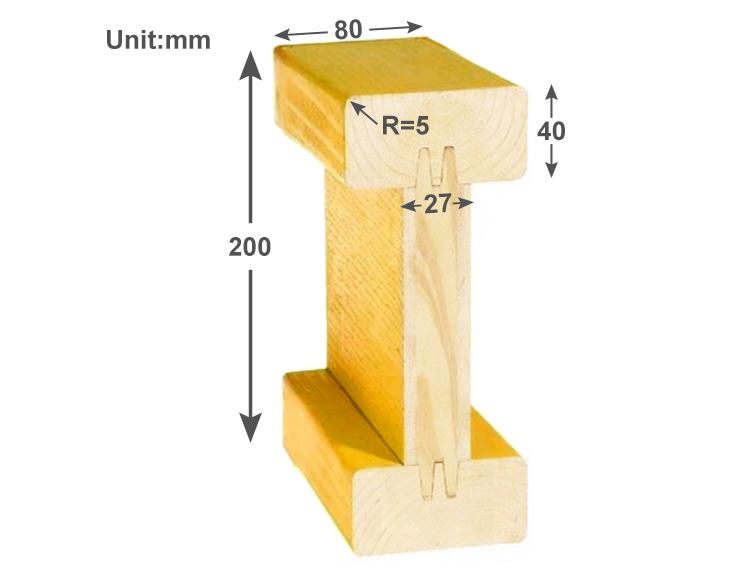

Moreover, the materials used in the manufacturing of falsework play a vital role in its effectiveness. Traditionally made from timber, modern falsework systems are increasingly utilizing steel and aluminum due to their high strength-to-weight ratios and durability. These materials allow manufacturers to design lighter yet powerful support systems that can be easily assembled and disassembled, a crucial factor for time-sensitive projects. Furthermore, advancements in technology have enabled the development of modular falsework systems that can be repurposed for multiple projects, leading to increased sustainability in construction practices.

Safety is another paramount concern in both falsework manufacturing and bridge construction. The use of high-quality materials and adherence to strict safety standards are non-negotiable in this industry. Manufacturers must ensure that their falsework systems are compliant with local regulations and international standards, thus minimizing the risk of accidents on-site. Regular inspections, load testing, and rigorous quality control protocols form the backbone of reputable falsework manufacturers. Their commitment to safety ultimately protects the workforce and contributes to the successful completion of projects on time and within budget.

Furthermore, the rise of digital construction technologies has transformed the landscape for falsework manufacturers. Computer-aided design (CAD) and Building Information Modeling (BIM) allow for precise modeling of falsework systems and more efficient coordination among project stakeholders. This digital approach enables manufacturers to foresee and address potential issues before construction begins, resulting in a smoother workflow and improved project outcomes.

In conclusion, the role of falsework bridge manufacturers is integral to the successful execution of bridge construction projects. Their ability to provide customized, safe, and efficient temporary support structures not only facilitates the construction process but also ensures that the final product is safe and durable. As infrastructure demands continue to grow globally, the innovation and expertise of falsework manufacturers will be essential in building bridges that stand the test of time, showcasing engineering prowess and commitment to safety.

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

H20 Timber Beam Enhanced with GPT-4-Turbo AI Design

NewsAug.01,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025

-

High Quality China Single Sided Wall Formwork for Retaining Walls

NewsJul.30,2025