Ное . 05, 2024 20:16 Back to list

h20 formwork beams company

The Evolution and Impact of H20 Formwork Beams in Construction

In the modern construction industry, efficiency, durability, and safety are paramount. Among the innovations that have shaped contemporary building practices, H20 formwork beams have emerged as a game-changer, revolutionizing the way structures are formed and supported during construction. This article delves into the features, advantages, and applications of H20 formwork beams, shedding light on why they have become an essential component in the construction toolkit.

What Are H20 Formwork Beams?

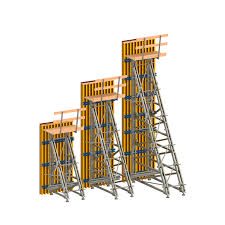

H20 formwork beams, also known as H20 timber beams or H20 formwork girders, are engineered wood products designed specifically for use in formwork systems. Characterized by their “H” shape, these beams offer a unique combination of lightweight design and high load-bearing capacity. The H-shaped cross-section enhances their structural stability, allowing for effective distribution of loads during construction phases. Typically, these beams are made from laminated veneer lumber or plywood, which provides improved resistance to bending and deformation compared to conventional timber.

Advantages of H20 Formwork Beams

1. Lightweight Design One of the standout features of H20 beams is their lightweight nature. This makes them easier to handle and transport, reducing labor costs and increasing efficiency on the job site. Workers can quickly assemble and disassemble the formwork, leading to significant time savings during the construction process.

2. High Load Capacity Despite their lightweight design, H20 beams are engineered to support heavy loads. They can effectively carry the weight of freshly poured concrete and the associated formwork, making them suitable for a variety of applications, including slab formwork and wall systems.

3. Durability and Longevity Constructed from high-quality materials, H20 formwork beams are resistant to warping and moisture damage. This durability extends the lifespan of the formwork system, resulting in lower costs over time as replacements and repairs are minimized.

h20 formwork beams company

4. Versatility H20 beams can be used in a range of applications, from residential buildings to large-scale commercial projects. They can easily adapt to various formwork configurations, facilitating creative architectural designs while maintaining structural integrity.

5. Enhanced Safety The robust design of H20 beams contributes to improved site safety. Their stability and strength reduce the risk of formwork failure, protecting workers and ensuring a smoother construction process.

Applications in the Construction Industry

H20 formwork beams are employed in various construction scenarios, making them a preferred choice among contractors and builders. Common applications include

- Slab Formwork H20 beams provide essential support for concrete slabs, ensuring uniform load distribution and reducing the risk of cracking. - Wall Forms They are utilized in wall formwork systems, allowing for the efficient construction of vertical structures with the necessary support for concrete curing. - Bracing Systems In addition to vertical and horizontal applications, H20 beams can also be used in bracing systems to stabilize temporary structures.

Conclusion

The introduction of H20 formwork beams has transformed the landscape of the construction industry. Their lightweight yet durable design, combined with high load capacity and versatility, make them an invaluable tool for builders seeking efficient and safe construction methods. As the industry continues to evolve, innovations like H20 formwork beams will play a crucial role in shaping the future of construction, allowing for quicker project completion and enhanced structural integrity.

In summary, H20 formwork beams represent more than just a construction material; they symbolize progress in the pursuit of efficiency, safety, and quality in building practices. As the demand for sustainable and resilient infrastructure grows, the prominence of H20 beams in formwork applications is likely to increase, paving the way for new possibilities in the construction field.

-

Steel Acrow Props - High-Strength Adjustable Shoring Solutions

NewsMay.16,2025

-

Durable One-Sided Wall Formwork Systems Custom Solutions & Export

NewsMay.16,2025

-

Heavy Duty Prop EN1065 Suppliers High-Capacity Support Solutions

NewsMay.16,2025

-

Formwork Scaffold Systems Reliable Suppliers & Durable Solutions

NewsMay.15,2025

-

Premium Shuttering Scaffolding Solutions Reliable Exporter & Suppliers

NewsMay.15,2025

-

Steel Props for Shuttering Suppliers Durable & Adjustable Solutions

NewsMay.15,2025