ऑगस्ट . 14, 2024 01:26 Back to list

Leading Manufacturer of Durable Steel Formwork Solutions for Concrete Construction Projects Worldwide

The Role of Concrete Formwork Steel Manufacturers in Modern Construction

In the ever-evolving landscape of construction, the demand for efficiency, durability, and cost-effectiveness is paramount. One of the critical components that supports these demands is concrete formwork, particularly steel formwork. As urban development continues to rise, the need for innovative solutions in construction has led to a surge in the prominence of concrete formwork steel manufacturers.

Concrete formwork is a temporary mold used to shape and support the concrete until it sets and hardens. Steel formwork, in particular, has become increasingly favored due to its robustness, reusability, and ability to deliver a high-quality finish. Manufacturers in this sector play a vital role by producing specialized formwork systems tailored to various construction needs.

Advantages of Steel Formwork

One of the primary advantages of steel formwork is its durability. Unlike traditional wooden formwork, steel can withstand the rigors of repeated use. This durability translates into lower long-term costs for construction firms. Steel formwork can be reused multiple times without significant wear and tear, optimizing resource utilization and minimizing waste.

Additionally, steel formwork provides superior dimensional accuracy. This feature is crucial for modern architectural designs that require precise measurements and alignment. Structural integrity is enhanced when formwork is accurately constructed and maintained. Manufacturers focus on precision engineering, ensuring that their products meet stringent standards, which ultimately contributes to the overall quality of the construction.

Innovation and Customization

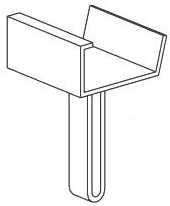

concrete formwork steel manufacturer

In today’s market, customization and innovation are key differentiators for concrete formwork steel manufacturers. Advanced manufacturing techniques, such as computer-aided design (CAD) and robotic welding, enable manufacturers to produce formwork that meets specific project requirements. Whether it’s a high-rise building or a complex infrastructure project, manufacturers can develop customized solutions that address unique challenges.

Moreover, recent advancements in materials technology have allowed manufacturers to enhance the performance of steel formwork. Incorporating lightweight alloys and innovative coatings can improve corrosion resistance and ease of handling, making it more accessible for construction workers. As sustainability becomes increasingly important, manufacturers are also exploring environmentally friendly practices, such as sourcing recyclable materials and reducing energy consumption during production.

The Manufacturer’s Role in Safety and Compliance

Safety is a fundamental concern in construction, and concrete formwork steel manufacturers are heavily invested in ensuring that their products adhere to industry standards and regulations. This commitment not only protects workers on-site but also instills confidence in project stakeholders. Comprehensive testing and certification processes ensure that formwork systems can withstand the pressures and conditions encountered during construction.

Manufacturers often collaborate with engineers and architects to ensure that their formwork solutions are safe and effective. This collaborative approach leads to a better understanding of the specific needs of each project and allows for the incorporation of best practices related to safety and efficiency.

Conclusion

Concrete formwork steel manufacturers are essential partners in the construction industry, contributing to the realization of ambitious architectural projects. Their commitment to durability, innovation, and safety plays a pivotal role in advancing modern construction techniques. As the industry continues to evolve, the collaboration between builders and manufacturers will be critical in overcoming challenges and achieving sustainable, cost-effective solutions that meet the demands of contemporary infrastructure development. As such, investing in high-quality steel formwork not only enhances the safety and efficiency of construction processes but also ensures the longevity and sustainability of the built environment.

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025

-

Formwork Spring Clamp Factories: Quality & Bulk Supply

NewsAug.21,2025

-

Premium Ringlock Scaffolding | China Manufacturer & Supplier

NewsAug.19,2025

-

Efficient Table Formwork for Fast Slab Construction & Reusability

NewsAug.18,2025

-

Timber Beam H20 Formwork & Shuttering - Durable & Reliable

NewsAug.17,2025