Jul . 26, 2024 15:55 Back to list

Procedure for Removing Formwork from Concrete Slabs in OEM Construction Projects

The OEM Removal of Formwork for Slabs A Practical Guide

Formwork is an essential component in the construction industry, primarily used for creating molds into which concrete is poured to form structures such as slabs, beams, and columns. The process of removing this formwork—referred to as OEM (Original Equipment Manufacturer) removal—requires careful planning and execution to ensure safety, structural integrity, and efficiency.

Understanding Formwork

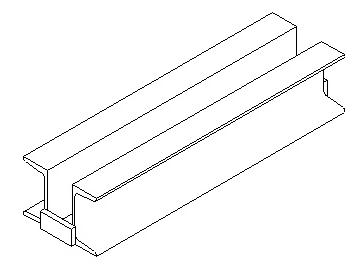

Formwork serves various functions during the construction process, including shaping the concrete, providing support until the material sets, and ensuring quality finishes. Depending on the project scale and complexity, formwork can be made from timber, steel, aluminum, or plastic, each material offering unique advantages.

The Importance of OEM Removal

The method and timing of formwork removal are critical. Early removal can lead to structural weaknesses and inefficiencies, while delaying the process can incur additional costs and affect project timelines. Proper OEM removal involves understanding the type of formwork in use, the curing period of the concrete, and ensuring that the concrete has gained adequate strength to support itself.

Factors Influencing Removal Timing

1. Type of Formwork Used Different materials have varying capabilities in supporting concrete. For instance, aluminum formwork is often removed quicker than traditional timber, due to its lightweight and quick assembly properties.

2. Environmental Conditions Temperature and humidity levels can affect the curing process of concrete. Warmer temperatures can speed up curing time while excessive humidity can hinder it. Therefore, these factors should be monitored closely.

oem removal of formwork for slab

3. Concrete Strength The most vital factor in the OEM removal of formwork is the compressive strength of the concrete. Generally, the removal can be carried out when the concrete reaches about 70% of its design strength, which is usually tested using standard methodologies.

4. Safety Considerations Safety is paramount during the formwork removal process. Workers need to be trained to handle the equipment safely and follow established protocols to prevent accidents. It is vital to inspect both the formwork and the concrete before removal.

Steps for Efficient OEM Removal

1. Preparation Before removal begins, a thorough inspection of the concrete is necessary to ensure it has enough strength to support itself. Additionally, assess the formwork for any damage or wear.

2. Communication Clear communication among the construction team is essential. All workers must be informed about the schedule and the steps involved in the removal process.

3. Removal Technique Formwork should be removed carefully and systematically. For example, when dealing with panel formwork, start from the edges and work towards the center. This minimizes stress on the newly cured concrete and reduces the risk of cracking.

4. Post-Removal Inspection After the formwork has been taken off, conduct an inspection of the slab for any potential issues such as voids or surface imperfections. This is crucial for ensuring the quality and durability of the slab.

Conclusion

The OEM removal of formwork for slabs is a critical phase in construction that requires careful planning and execution. By understanding the factors affecting removal timing, adhering to safety protocols, and following best practices, construction teams can ensure that their projects proceed smoothly and efficiently. A successful formwork removal not only contributes to the structural integrity of a project but also enhances the overall quality of the construction process. In an industry where precision and quality are paramount, mastering this aspect of formwork management can significantly impact project outcomes.

-

Advanced Column Formwork with GPT-4 Turbo | Efficient Construction

NewsAug.04,2025

-

Premium Wall Formwork Solutions for Modern Construction

NewsAug.03,2025

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

H20 Timber Beam Enhanced with GPT-4-Turbo AI Design

NewsAug.01,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025