अगस्ट . 10, 2024 00:50 Back to list

Innovative Company Offering Metal Scaffolding Solutions and Durable Cross Braces for Construction Projects

The Importance of Metal Scaffold Cross Braces in Construction A Company Perspective

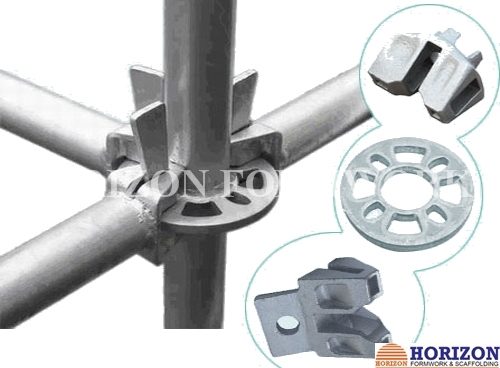

In the realm of construction, safety and structural integrity are paramount. As projects grow in scale and complexity, the demand for reliable support systems becomes increasingly vital. This is where metal scaffold cross braces come into play. Numerous companies specialize in manufacturing and supplying these essential components, focusing on reliability, durability, and safety. In this article, we'll explore the significance of metal scaffold cross braces in construction and highlight what makes companies in this niche crucial to the industry.

The Importance of Metal Scaffold Cross Braces in Construction A Company Perspective

When selecting a company that supplies metal scaffold cross braces, several factors come into play. First and foremost is the quality of the materials used. Companies that prioritize high-grade metals, such as galvanized steel or aluminum, ensure that their products are long-lasting and capable of withstanding harsh environmental conditions. The corrosion resistance of galvanized steel, for instance, can significantly extend the life span of scaffolding, reducing replacement costs and enhancing safety.

metal scaffold cross braces company

Another critical aspect that sets successful companies apart is their commitment to adhering to safety standards and regulations. ISO certifications and compliance with Occupational Safety and Health Administration (OSHA) guidelines not only boost a company's credibility but also ensure that their products meet the high safety standards required in construction. Companies that invest in regular audits and quality control measures demonstrate their dedication to producing reliable and safe scaffolding solutions.

Moreover, innovation plays a significant role in the development of metal scaffold cross braces. Companies that are willing to invest in research and development can introduce advanced designs that improve ease of installation and transportability. For instance, some modern cross braces utilize quick-release mechanisms, enabling construction teams to set up and dismantle scaffolding more efficiently. This not only saves time but also enhances workplace productivity and minimizes labor costs.

Customer support and service are additional attributes that contribute to a company's reputation in the scaffold supply industry. A supplier that offers comprehensive support, including guidance on proper assembly techniques and safety training for workers, can significantly impact the overall safety and effectiveness of scaffolding use on-site. Additionally, responsive customer service ensures that construction teams can quickly obtain replacement parts or resolve issues during the hectic pace of a project.

In conclusion, the role of metal scaffold cross braces in construction cannot be overstated. As the backbone of scaffolding systems, they provide essential support that impacts both the safety and efficiency of construction projects. Companies that specialize in the manufacture and supply of these braces must focus on quality materials, adherence to safety standards, innovation, and customer service to thrive in this competitive market. By investing in these areas, they not only strengthen their market position but also contribute significantly to the safety and success of the construction industry as a whole. As we move towards larger and more complex construction projects, the importance of dependable scaffolding solutions, including metal scaffold cross braces, will only continue to rise.

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025

-

Adjustable Heavy Duty Props for Slab Formwork | Strong & Reliable Support

NewsAug.23,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Strong & Safe Support

NewsAug.22,2025