Nov . 05, 2024 09:07 Back to list

assembled table formwork manufacturer

Assembled Table Formwork A Comprehensive Overview of Manufacturers and Their Impact

In the construction industry, the effective use of formwork systems is crucial for ensuring the stability and quality of concrete structures. Among the various formwork solutions available, assembled table formwork has gained significant popularity due to its efficiency, versatility, and ease of use. This article explores the key aspects of assembled table formwork manufacturers, highlighting their contributions to construction projects worldwide.

Assembled table formwork is designed to support large slabs and ceilings during the pouring and curing of concrete. These systems consist of prefabricated panels that can be easily assembled on-site, reducing labor time and associated costs. Additionally, this type of formwork is lightweight, allowing for quick repositioning and reuse in multiple projects, thereby offering substantial savings for contractors.

Leading manufacturers of assembled table formwork place a strong emphasis on innovation and technology. They continuously seek to improve their products by integrating advanced materials and design techniques. For instance, many companies utilize high-strength aluminum and steel in their formwork systems, which not only enhances durability but also makes the components easier to handle. Such advancements allow manufacturers to create lighter, yet more robust formwork systems that can withstand the rigors of construction while maximizing efficiency.

One of the notable advantages of assembled table formwork is its adaptability to various project sizes and requirements. Manufacturers often provide customizable solutions that can be tailored to fit unique architectural designs. This flexibility is essential in meeting the demands of modern construction, where bespoke designs are increasingly common. Furthermore, many manufacturers offer comprehensive support, including training for construction teams, which ensures the proper installation and operation of the formwork systems.

assembled table formwork manufacturer

Environmental sustainability is another key focus area for many assembled table formwork manufacturers. With the global shift towards sustainable construction practices, these manufacturers are taking strides to minimize their environmental impact. This includes using recyclable materials in their products and developing systems that can be reused for multiple projects. By doing so, manufacturers not only contribute to greener building practices but also align with the growing demand for environmentally friendly construction solutions.

Globalization has also impacted the way formwork manufacturers operate. Many of them now have a strong international presence, allowing them to serve clients in various regions. This global perspective enables them to gather insights from diverse markets, leading to the development of more refined and effective formwork solutions. Moreover, international collaborations have resulted in the sharing of best practices, fostering innovation in product design and application.

Assembled table formwork manufacturers are continually adapting to the changing landscape of the construction industry. They are increasingly leveraging digital technologies, such as building information modeling (BIM), to streamline the planning and execution of construction projects. By incorporating these technologies, manufacturers can provide accurate visualizations of formwork systems, facilitate better project management, and enhance overall efficiency.

In conclusion, assembled table formwork manufacturers play a pivotal role in the construction sector by providing efficient, adaptable, and sustainable solutions. With a focus on innovation, customization, and environmental responsibility, these manufacturers are well-equipped to meet the evolving demands of the industry. As construction projects become more complex and sustainability becomes increasingly important, the contributions of assembled table formwork manufacturers will continue to be invaluable in shaping the future of building practices worldwide. Their commitment to quality and innovation not only benefits contractors but also contributes to the creation of safer and more sustainable structures for the communities they serve.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

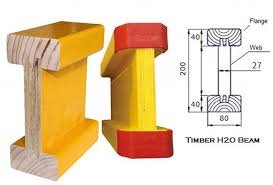

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025