Dec . 04, 2024 10:12 Back to list

bridge deck formwork supplier

Selecting the Right Bridge Deck Formwork Supplier

When undertaking a bridge construction project, one of the pivotal decisions is selecting the right formwork supplier. Bridge deck formwork is essential for ensuring the structural integrity and durability of the bridge while also impacting the efficiency of construction processes. As such, the choice of a formwork supplier can significantly influence both the budget and timeline of the project. Here’s what you should consider when looking for a reliable bridge deck formwork supplier.

Understanding the Importance of Formwork

Formwork is a temporary structural support that molds concrete into the desired shape until it sets. For bridge decks, this means creating the necessary shape for the roadway while also accommodating reinforcement bars and drainage systems. Quality formwork is crucial for achieving precise dimensions, smooth surface finishes, and overall structural safety. Poorly designed or cheap formwork can lead to delays, safety hazards, and increased costs. Therefore, selecting a reputable supplier is paramount.

Key Factors to Consider

1. Experience and Expertise Begin by evaluating the supplier’s experience in the industry. A supplier with a long track record in providing bridge deck formwork is likely to have the knowledge and technical expertise necessary to meet specific project requirements. Look for case studies or references from similar projects to gauge their competence.

2. Product Quality The materials used in formwork can greatly affect performance. A reputable supplier will offer high-quality materials that are durable, lightweight, and easy to assemble. Consider suppliers that use advanced technology and innovative materials, such as fiberglass or engineered wood, which can enhance performance and reduce weight, making them easier to handle on-site.

bridge deck formwork supplier

3. Custom Solutions Every bridge project is unique, and a one-size-fits-all approach rarely works in construction. A competent formwork supplier should offer custom solutions tailored to specific project needs. This could entail bespoke formwork designs that take into account unique loads, dimensions, and environmental conditions.

4. Technical Support and Training A good supplier doesn’t just sell formwork; they provide support throughout the construction process. This includes technical assistance during installation, guidance on best practices, as well as training for your crew. Ensure that the supplier has a robust support system in place, as this can save time and mitigate issues during construction.

5. Safety Standards Safety is paramount in construction. Your formwork supplier should adhere to industry safety standards and regulations, providing formwork solutions that minimize risk. Inquire about their safety protocols and whether they offer safety certification for their products.

6. Cost and Value While it can be tempting to go with the cheapest option, it is essential to assess the overall value and not just the upfront cost. Sometimes, investing in higher quality formwork from a reputable supplier can reduce labor costs and project delays in the long run, proving to be a more economical choice.

7. Client Reviews and Testimonials Researching reviews and testimonials can provide insight into the experiences of previous clients. Look for feedback regarding the supplier’s reliability, product performance, and after-sales service. Online forums and construction industry groups can be valuable resources for gathering unfiltered opinions.

Conclusion

The selection of a bridge deck formwork supplier plays a crucial role in the success of a bridge construction project. Taking the time to research potential suppliers based on experience, product quality, custom solutions, technical support, safety standards, and value can make a significant difference in both the efficiency and outcome of the project. Investing in a quality supplier not only ensures the structural integrity of the bridge but also enhances the overall construction experience. As the saying goes, “You get what you pay for,” so aim for suppliers that provide a good balance of quality and cost-effectiveness, and your project will be well on its way to success.

-

Durable Powder Coating Steel Formwork Enhanced Lifespan & Protection

NewsJun.03,2025

-

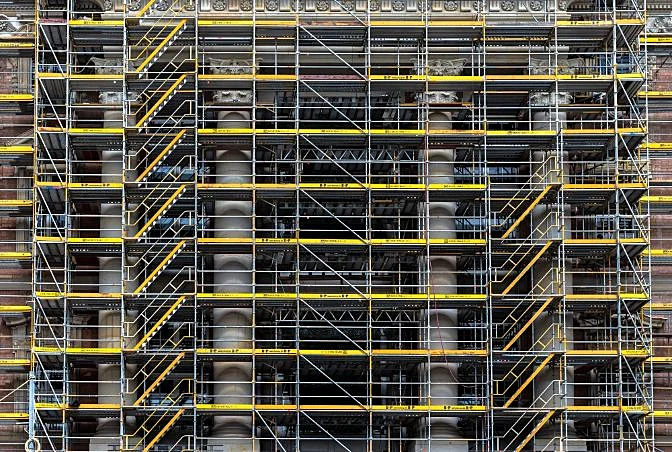

Industrial High Load Scaffolding Suppliers Safe Heavy-Duty Solutions

NewsJun.03,2025

-

Prop 30-350 Premium Table Forms for Exporters & Suppliers

NewsJun.03,2025

-

Custom Falsework Systems for Construction Durable & Adjustable Solutions

NewsJun.03,2025

-

China Scaffolding Jacks - Durable & Adjustable Construction Solutions

NewsJun.03,2025

-

Euro Scaffolding Suppliers Durable & Custom Solutions

NewsJun.02,2025