Dec . 05, 2024 03:08 Back to list

Establish a Metal Scaffolding Production Facility for Construction Industry Needs

Building a Metal Scaffold Factory An Overview

As the construction industry continues to evolve, the demand for high-quality scaffolding systems has significantly increased. Metal scaffolding, known for its durability, safety, and efficiency, plays a crucial role in modern construction projects. In this context, establishing a metal scaffold factory presents a promising opportunity to meet this growing demand. Here, we explore the key aspects of building a metal scaffold factory, from market analysis to production processes and sustainability considerations.

Market Analysis

Before embarking on the journey of establishing a metal scaffold factory, a thorough market analysis is essential. The construction sector is projected to grow substantially in the coming years, fueled by urbanization, infrastructural developments, and an increase in mega-projects across the globe. This growth translates into a rising need for scaffolding solutions. Identifying potential customers, including construction companies, rental firms, and international markets, will help in tailoring production to meet specific demands. Additionally, understanding the competitive landscape will aid in formulating effective strategies for differentiation.

Facility and Equipment Setup

Once the market analysis is complete, the next step is to determine the location and layout of the factory. Selecting a site that is strategically positioned near major construction hubs and transportation networks will facilitate logistics and reduce costs. The layout should be designed for optimal workflow, ensuring that each stage of production operates smoothly.

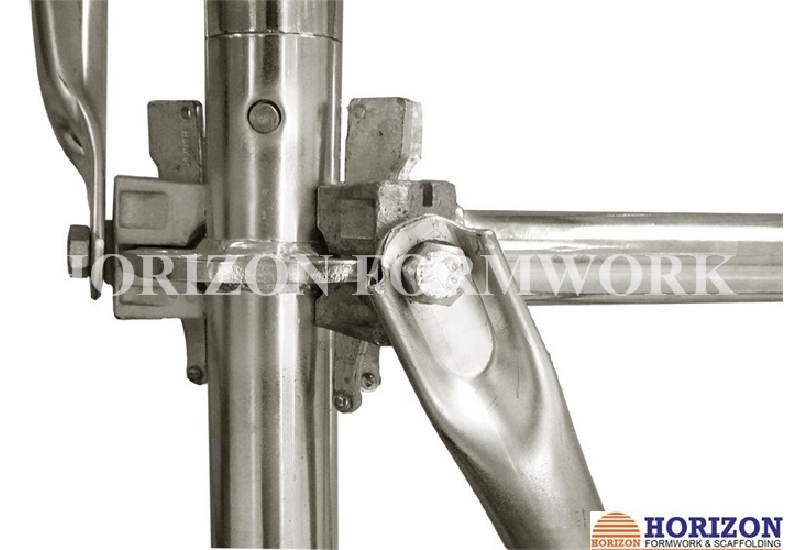

When it comes to equipment, investing in state-of-the-art machinery is crucial. The production process for metal scaffolding typically involves cutting, welding, and finishing metal components. Automated cutting machines, robotic welders, and powder-coating lines can significantly enhance productivity and ensure consistent quality. Additionally, implementing quality control measures at every stage of production will help maintain high standards and minimize defects.

Sourcing Materials

The production of metal scaffolding requires high-quality raw materials, primarily steel or aluminum. Establishing reliable relationships with suppliers is paramount to ensure a consistent supply chain. Moreover, considering recycled materials can not only reduce costs but also appeal to environmentally-conscious customers. Implementing a procurement strategy that emphasizes sustainability can further enhance the factory’s reputation and marketability.

build a metal scaffold factory

Skilled Workforce

A skilled workforce is essential for the successful operation of a metal scaffold factory. Investing in training and development programs will enable employees to gain expertise in modern manufacturing techniques and safety standards. Moreover, fostering a positive workplace culture will improve retention rates and overall productivity. Collaboration with local technical schools or vocational training centers can provide a pipeline of skilled workers ready to enter the industry.

Safety and Compliance

Safety is paramount in the manufacturing of scaffolding systems. Adhering to safety regulations and standards set by organizations such as OSHA (Occupational Safety and Health Administration) is crucial to protect workers and ensure the quality of the products. Regular safety drills, equipment maintenance, and compliance audits should be integral parts of the factory's operational procedures.

Sustainability Initiatives

In today’s environmentally-conscious world, implementing sustainable practices in the production process is not just a trend; it's a necessity. Using energy-efficient machinery, recycling waste materials, and minimizing emissions can significantly reduce the factory's environmental footprint. Moreover, promoting sustainability in the marketing strategy can attract a broader customer base, particularly those prioritizing eco-friendly construction practices.

Conclusion

Building a metal scaffold factory is a multifaceted venture that entails careful planning, execution, and ongoing management. By conducting thorough market research, investing in modern technology, and prioritizing safety and sustainability, entrepreneurs can create a successful enterprise that meets the growing needs of the construction industry. With the right approach, a metal scaffold factory not only promises profitability but also contributes positively to the wider community and environment. As the construction industry continues to expand, so too does the opportunity for manufacturers to forge a path forward in this dynamic field.

-

Heavy Duty Prop | EN1065 Shoring Props for Formwork & Slabs

NewsSep.01,2025

-

Formwork Spring Clamp Factories | Quality & Durable Spring Clamps

NewsAug.31,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Max Load & Safety

NewsAug.30,2025

-

Premium Formwork Wing Nuts & Tie Rods | Factory Supplier

NewsAug.29,2025

-

Expert Ringlock Scaffolding: Durable, Safe, Efficient Solutions

NewsAug.28,2025

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025