Dec . 04, 2024 06:45 Back to list

Constructing a Durable Metal Scaffold for Efficient Construction Projects

Building a Metal Scaffold A Comprehensive Guide

In the modern construction industry, scaffolding is a critical element that ensures safety, accessibility, and efficiency. Among the various types of scaffolding available, metal scaffolds have gained prominence due to their strength, durability, and adaptability. This article aims to provide a comprehensive overview of building a metal scaffold, emphasizing the key components, procedures, and safety measures that are essential for successful installation.

Understanding Metal Scaffolding

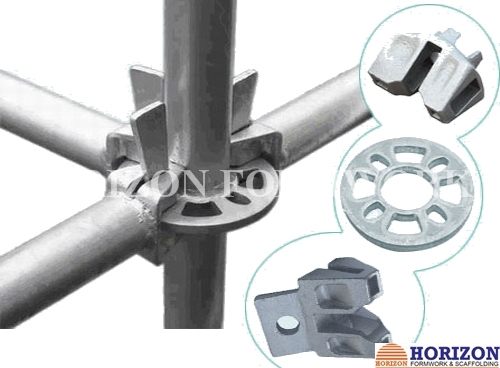

Metal scaffolding typically comprises steel or aluminum frameworks that support workers and materials during construction activities. These scaffolds can be categorized into different types, such as modular, system, and traditional scaffolding. Each type is designed to cater to specific needs and project requirements, making metal scaffolding a versatile choice in various construction settings.

Key Components of Metal Scaffolds

1. Standards Vertical posts that provide the primary support for the scaffold structure. They are crucial for maintaining stability and must be anchored securely to the ground.

2. Ledgers Horizontal beams that connect the standards. They provide lateral support and help to distribute the load evenly across the scaffolding.

3. Braces Diagonal supports that enhance the rigidity of the scaffold. They are essential in preventing any lateral movement and ensuring that the structure remains stable, especially in windy conditions.

4. Platforms The working surfaces where workers perform their tasks. These can be made from plywood, steel decks, or aluminum planks, and should be installed securely to prevent any accidents.

5. Toe Boards Horizontal barriers installed at the edge of the platform to prevent tools and materials from falling off, ensuring a safer work environment.

6. Access Points Ladders or stairways that allow workers to enter and exit the scaffold safely. These must be designed to meet safety regulations and should be securely attached to the scaffold.

Procedure for Building Metal Scaffolds

Building a metal scaffold requires careful planning and execution

. Here is a step-by-step guidechina build a metal scaffold

1. Planning and Design Before beginning construction, it is vital to assess the site and determine the scaffold's design based on the specific requirements of the project. Factors such as height, load capacity, and work environment should be considered.

2. Site Preparation Clear the work area of any debris, ensuring a safe and stable foundation for the scaffold. If necessary, use pads or footings to further stabilize the base.

3. Erecting Standards Begin by placing the vertical standards at regular intervals, ensuring they are plumb and securely anchored.

4. Attaching Ledgers Connect the ledgers to the standards at the specified heights. Ensure that they are level and properly secured.

5. Installing Braces Position the braces diagonally between standards to enhance stability. Each brace should be installed in a consistent manner to maintain uniformity.

6. Laying Platforms Install the platforms securely, ensuring there are no gaps that could cause accidents. Properly secure any loose fittings or connections.

7. Adding Toe Boards and Access Points Install toe boards around the edges of the platforms and set up safe access points. Make sure that all components are securely fastened.

Safety Measures

Safety is paramount when constructing and using metal scaffolds. Some essential safety measures include

- Regular inspections Conduct routine checks to ensure that the scaffold structure is intact and stable. - Training Ensure that all workers are trained in scaffold safety and proper usage. - Adhering to regulations Familiarize yourself with local safety codes and regulations governing scaffolding.

Conclusion

Building a metal scaffold is a crucial skill in the construction industry. By understanding the key components, following the correct procedures, and adhering to safety measures, workers can ensure a safe and effective working environment. As construction projects continue to evolve, metal scaffolding will remain an essential tool, contributing to the efficiency and success of various endeavors.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025