Nov . 06, 2024 21:11 Back to list

Innovative Climbing Formwork Solutions for Efficient Construction Projects

The Innovations Behind Climbing Formwork A Modern Solution from the Factory

In the world of construction, the methods and materials we use significantly impact both the efficiency and quality of our projects. Among the innovations that have revolutionized construction practices is climbing formwork, a system that provides remarkable benefits in building tall structures, particularly skyscrapers and bridges. The climbing formwork factory stands at the forefront of this innovation, producing sophisticated systems that cater to the ever-evolving demands of modern construction.

Understanding Climbing Formwork

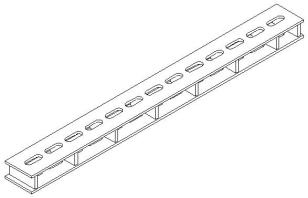

Climbing formwork is a temporary structure used to support the materials being poured to create vertical elements like walls and columns. Unlike traditional formwork, which is assembled and then dismantled after the concrete cures, climbing formwork is designed to rise along with the construction, climbing as the structure progresses. This method not only saves time but also enhances safety and improves the overall structural integrity of the building.

One of the key features of climbing formwork systems is their ability to create smooth, precise surfaces, which is essential for high-rise buildings. The systems are engineered to accommodate various loads and can handle the demands of concrete pouring operations efficiently. This innovation not only streamlines the process but also reduces labor costs, making it an attractive option for contractors.

The Role of the Climbing Formwork Factory

The climbing formwork factory plays a pivotal role in the construction industry by supplying these advanced systems

. With a focus on quality and safety, these factories employ cutting-edge technology and skilled professionals to ensure that every product meets stringent standards. Each system is designed with modular components that can be easily transported and assembled on-site, allowing for quick adaptation to the specific needs of different projects.Moreover, climbing formwork factories are equipped to provide customized solutions. Depending on the specifications of a project, engineers can design formwork systems that accommodate unique architectural elements or complex structural requirements. This flexibility is crucial as it allows construction teams to maintain project timelines without compromising on design or safety.

climbing formwork factory

Advantages of Climbing Formwork

1. Efficiency One of the most significant benefits of climbing formwork is its efficiency. As construction progresses, the formwork can be automatically raised, minimizing downtime and allowing for continuous operation. This feature is especially beneficial in skyscraper construction, where the need to maintain a rapid pace is critical.

2. Safety Safety is a paramount concern in construction. Climbing formwork systems are designed with safety features that protect workers during the pouring process. For instance, the platforms often include guardrails and provide stable, level surfaces, reducing the risk of accidents.

3. Cost-Effectiveness Although the initial investment in climbing formwork may be higher than traditional methods, the long-term savings are significant. Reduced labor costs, decreased material waste, and shorter project timelines contribute to an overall decrease in project expenses.

4. Environmental Impact Modern climbing formwork systems are often designed with sustainability in mind. Factories are now focusing on using eco-friendly materials and processes, and the efficient use of resources contributes to lower energy consumption during construction.

Conclusion

As the construction industry continues to grow, the role of climbing formwork becomes more pronounced. The climbing formwork factory not only supplies essential materials but also plays a vital part in driving innovation and efficiency in building practices. With its numerous advantages, climbing formwork is set to become a standard practice in constructing tall structures. As we look to the future, the advancements in this field promise to deliver even more efficient, safer, and sustainable building solutions, demonstrating that the construction industry is indeed evolving to meet the challenges of a changing world.

-

Heavy Duty Prop | EN1065 Shoring Props for Formwork & Slabs

NewsSep.01,2025

-

Formwork Spring Clamp Factories | Quality & Durable Spring Clamps

NewsAug.31,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Max Load & Safety

NewsAug.30,2025

-

Premium Formwork Wing Nuts & Tie Rods | Factory Supplier

NewsAug.29,2025

-

Expert Ringlock Scaffolding: Durable, Safe, Efficient Solutions

NewsAug.28,2025

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025