Sep . 27, 2024 23:40 Back to list

Innovative Climbing Formwork Solutions for Efficient Pier Construction Projects

Climbing Formwork Pier Solutions Elevating Construction Efficiency

In the ever-evolving construction industry, efficiency and precision are paramount for project success. One of the technological advancements that have significantly contributed to streamlining operations is climbing formwork, particularly in the construction of piers. With the growing demand for fast-tracked construction projects, companies specializing in climbing formwork solutions are playing a crucial role in enhancing productivity and ensuring high-quality results.

Understanding Climbing Formwork

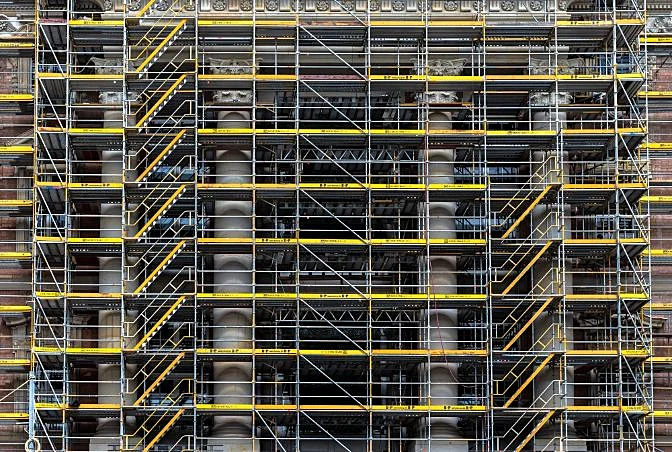

Climbing formwork is a modern formwork system that is designed for high-rise structures and vertical constructions, including bridges, towers, and piers. Unlike traditional formwork, which requires extensive manual handling and time for assembly and disassembly, climbing formwork is engineered to be self-climbing. It utilizes hydraulic or mechanical systems to climb up the structure as the concrete is poured and cured, thus keeping the workflow seamless and continuous.

This innovation minimizes downtime between cycles and significantly reduces labor costs, making it an attractive option for contractors. The ability to adjust the height of the formwork quickly allows for greater flexibility in managing project timelines, ultimately leading to faster completion rates while maintaining safety standards.

Advantages of Climbing Formwork for Piers

1. Time Efficiency With the ability to climb automatically, climbing formwork accelerates the construction process. This feature is especially beneficial for pier construction where timelines are often tight, allowing contractors to meet project deadlines without compromising quality.

2. Cost-Effectiveness Utilizing climbing formwork can lead to significant cost savings. The reduction in labor requirements and the efficient use of materials result in lower operational costs, which can be an essential factor when budgeting for large-scale projects.

climbing formwork pier company

3. Safety Enhancements Safety is a critical concern in construction projects. Climbing formwork systems are designed with built-in safety features that reduce the risk of accidents on-site. By minimizing the need for workers to be at higher elevations during the formwork process, these systems enhance overall safety for construction crews.

4. Quality Control The precision of climbing formwork contributes to greater structural integrity. The modular nature of the system allows for consistent concrete pouring and curing processes, resulting in high-quality finishes with fewer defects. This reliability is crucial in meeting the demanding engineering standards required for pier constructions.

5. Environmentally Friendly Many climbing formwork systems are designed to be reused multiple times, promoting sustainability in construction practices. This not only reduces waste but also lessens the environmental impact associated with manufacturing and transporting traditional formwork materials.

Choosing the Right Climbing Formwork Company

Selecting an experienced climbing formwork company is vital to achieving successful outcomes in pier construction. Potential clients should consider factors such as the company’s track record, the quality of its systems, and customer service. Engaging with manufacturers who provide comprehensive support and possess a deep understanding of the unique challenges associated with climbing formwork can make a significant difference in project execution.

Conclusion

Climbing formwork is transforming the landscape of construction for piers and vertical structures. As the industry continues to embrace technological advancements, companies that specialize in climbing formwork solutions are poised to deliver exceptional results. With increased time efficiency, cost-effectiveness, enhanced safety measures, and superior quality control, climbing formwork is undoubtedly reshaping how construction projects are approached, paving the way for more innovative and sustainable building practices.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025